Құрылғалы бері Xinmao автоматтандыру басқару инженерлері, бағдарламалық қамтамасыз ету инженерлері, өнеркәсіптік дизайнерлер, сатудан кейінгі қызмет инженерлері және т.б. кіретін көпсалалы кәсіби команданы жинақтады, клиенттердің тапсырыс бойынша қажеттіліктеріне негізделген жобалаудан бастап, жүйені интеграциялау, сатудан кейінгі оқыту, орнату және т.б. толық спектрлі жүйе қызметтерін ұсынады. Технологияларды зерттеу және дамыту тұрғысынан компания үздіксіз инвестиция салып, Индустрия 4.0 және интеллектуалды өндірістің соңғы трендтерімен бірге дамып келеді. Тәуелсіз әзірленген интеллектуалды басқару жүйесі заттар интернеті, үлкен деректер және жасанды интеллект сияқты озық технологияларды біріктіріп, жабдықтардың өзара байланысын, өндіріс процесінің нақты уақыттағы мониторингін және оңтайландыруын, сондай-ақ жеткізу тізбегінің тиімді ынтымақтастық басқаруын қамтамасыз етеді. Сонымен қатар, компания интеллектуалды қойма жабдықтары мен автоматтандырылған өндіріс желілері сияқты озық аппараттық өнімдерді де ұсынады, олар тұрақты өнім өнімділігі мен сенімді жұмысын қамтамасыз ету үшін қатаң сапа тексерулерінен өтеді.

| Сусындарды өңдеу жүйелері | |

| Жүйе | Жабдықтар |

| Су өңдеу | Алдын ала сүзу жүйесі\Мембраналық бөлу жүйесі\Стерилизация жүйесі |

| Алдын ала өңдеу жүйесі | Ерітінді бірлігі\Экстракция бірлігі\Ферментация бірлігі\Араластыру және тұрақты көлем бірлігі |

| UHT жүйесі\CIP жүйесі\дезинфекция жүйесі\көмірқышқыл газын араластыру | |

| Қаптау жүйесі | |

| Жүйе | Жабдықтар |

| Құю жүйесі | 0.25~15L |

| Құю жүйесі | Су құю\көмірқышқыл газымен сусын құю\сок ыстық құю\банкаға құю\сыра құю\сүт өнімдерін құю |

| Тасымалдау жүйесі | Ауа тасымалдаушы\бутылкаларды ретке келтіруші\бутылкаларды айналдыру тізбегі\спреймен салқындату туннелі\бутылкаларды жылыту\бутылка (қорап, паллет) тасымалдаушы |

| Сыртқы қаптау жүйесі | |

| Жүйе | Жабдықтар |

| Упаковочный автомат | Қорап қаптау машинасы/фильм қаптау машинасы |

| Бутылка (банка) паллетизатор (депаллетизатор) | PET бөтелкелер\банкалар\шыны бөтелкелер |

| Қорап паллетизатор (депаллетизатор) | Қорап\Пластикалық қорап |

| Таңбалау машинасы | Ыстық балқыту желімі\өздігінен жабысатын\суық желім\алдын ала жабылған желім |

| Ақылды зауытты басқару жүйесі | |

| Жүйе | Жабдықтар |

| Барлық желі үшін орталық электрлік басқару жүйесі | Операцияны бақылау\деректерді жинау\есеп\энергияны басқару |

| Сатудан кейінгі қызмет | 24 сағаттық тұтынушыларға қызмет көрсету ыстық желісі\техникалық мәселелерді жылдам шешу үшін қашықтан диагностика\кәсіби қолдау және техникалық оқыту |

1. Шынайы қызмет

"Тұтынушыларға идеалды зауыттар құруға көмектесу" корпоративтік миссиясын ұстана отырып, XINMAO жылдам жауап беру жылдамдығы, кәсіби техникалық деңгейі және қамқорлық қызмет көрсету态度сымен "тұтынушылардың күткенінен және салалық стандарттардан асып түсетін" қызметтерді жасайды және тұтынушылар үшін шын жүректен құн жасайды.

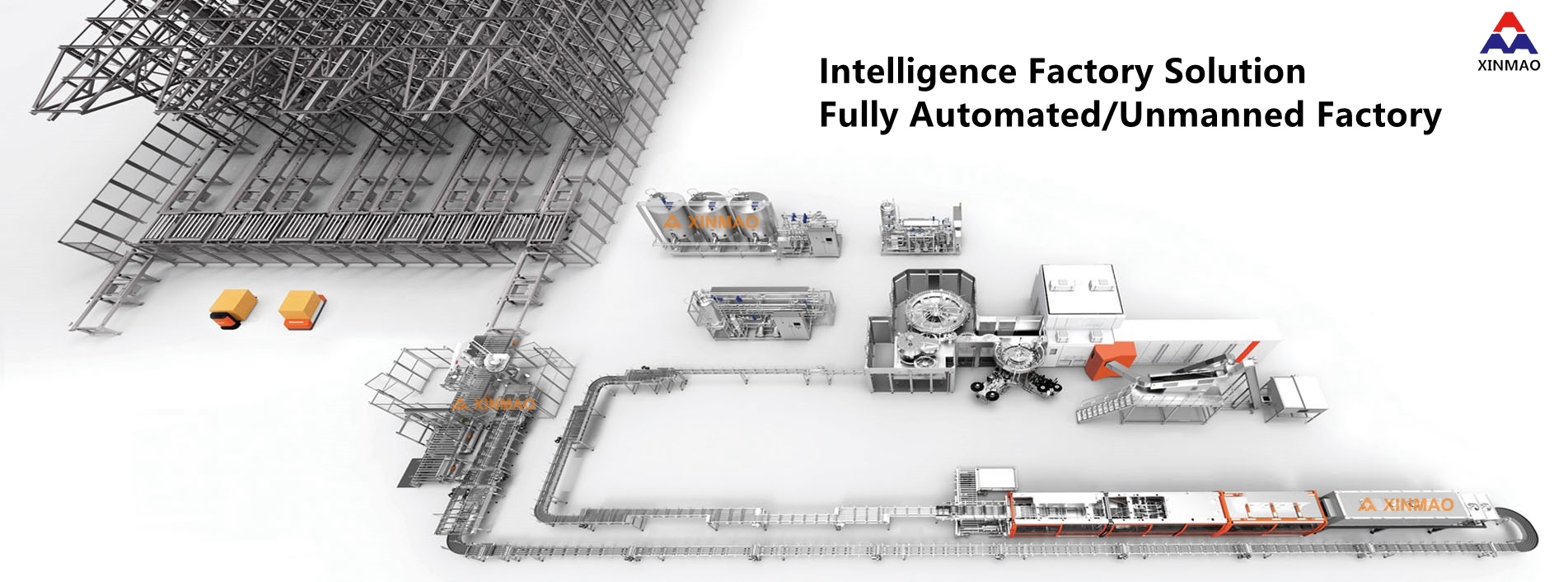

Толық зауыт жобасы

Жоғары сапалы жабдықтармен, мінсіз қызметтермен және толық зауыт үшін мықты "turnkey" қызмет көрсету мүмкіндіктерімен XINMAO тұтынушыларға жабдықтардың тиімді жұмысын, технологиялық инновацияларды және жаңартуларды жүзеге асыруға көмектеседі, сондай-ақ тұтынушылармен өзара тиімділікке қол жеткізеді.

Жергіліктегі сервистік қызмет

Жергілікті жағдайларға бейімделу және клиенттерге жеке және қамқорлық көрсететін қызметтер ұсыну - XINMAO-ның тұрақты мақсаты. XINMAO Инженерлік Орталығы инженерлік жобаларды сәтті жүзеге асыруды қамтамасыз ету үшін кәсіби және тамаша инженерлік жобалау, орнату және іске қосу командасына ие.

Сатудан кейінгі қолдау

Глобалдық нарықтың кеңеюімен XINMAO ішкі және шетелдегі қызмет көрсету орталықтарына сүйене отырып, әлемдік клиенттерге техникалық қолдау және сатудан кейінгі қызметтерді уақтылы ұсынады, сондай-ақ клиенттердің бизнесінің дамуына қолдау көрсетеді.

Қосалқы бөлшектер

Пайдаланушылардың не ойлайтынын және неге алаңдайтынын ойлай отырып, XINMAO клиенттердің зауыттарының жұмысын қамқорлықпен қарайды, олардың жабдықтарының тұрақты жұмысын толық қамтамасыз етеді және қосалқы бөлшектерді уақтылы қолдайды.

2. Қызмет Көзқарасы

Қызмет Мақсаты

Тұтынушыларға тиімділікті арттыру, шығындарды азайту, тұтынушының пайдасын және өнімнің құнын стандартталған, ерекшеленген және қосымша құнды қызметтер арқылы жақсартуға көмектесу, XINMAO қызмет бренді бәсекеге қабілеттілігін құру және сала қызметінің трендін басқару.

Жедел жауап

XINMAO тұтынушы қажеттіліктерін ең қысқа мерзімде толық қызмет платформасы мен жылдам жауап беру механизмі арқылы қанағаттандырады.

Белсенді тексеру

Инженерлер уақыт-уақытпен тұтынушы зауыттарына барып, жабдықтарды тексереді, жабдықтың жұмыс жағдайын түсінеді және тұтынушыларға шешімдер жобалауға көмектеседі.

3. Қызмет көрсету қолдауы

Техникалық қызмет көрсету жоспары

Өнім қауіпсіздігіне назар аудару және жабдықтарды стандартталған техникалық қызмет көрсету арқылы жабдықтың жақсы жұмыс жағдайында болуын қамтамасыз ету және қажетсіз қауіптерден аулақ болу. XINMAO әртүрлі жергілікті жағдайлар мен әдістерге негізделген тұтынушылар үшін жеке техникалық қызмет көрсету жоспарларын әзірлейді және тұрақты түрде алдын алу шараларын жүзеге асырып, шығындарды оңтайландырып, жабдықтың тұрақты және тұрақты жұмысын қамтамасыз етеді.

Тұтынушы пайдасы:

Орында тексеру

Тексеру

Реттелген тексерулер жабдықтың техникалық қызмет көрсетуін мақсатты түрде жоспарлауға және төтенше жағдайларға дайын болуға көмектеседі. Қызмет инженерлері сіздің машинаңыздың қазіргі жағдайын XINMAO техникалық стандарттарымен салыстыра отырып бағалайды, бұл сізге алдын ала құнды уақытты үнемдеуге және өндіріс жоспарыңызға әсер ететін күтпеген тоқтап қалулардан аулақ болуға мүмкіндік береді.

Капиталды жөндеу

Машинаның ұзақ мерзімді жұмысы тозатын бөлшектердің тозуына немесе компоненттердің аномальды жағдайларына әкеледі. XINMAO сізге барлық тозған бөлшектер мен компоненттерді мақсатты түрде ауыстыруға көмектеседі, бұл жабдықтың тұрақты және тұрақты жұмысын қамтамасыз етеді.

Кешенді техникалық қызмет көрсету жоспарының қолдауы

Техникалық қызмет көрсету

XINMAO қызмет инженерлері клиенттерге тәулік бойы техникалық кеңес, орындалған ақауларды сұрау және жөндеу жұмыстарын жүргізеді. Қиын мәселелер үшін біз мамандарды ақаудың себебін диагностикалауға ұйымдастырамыз. Қашықтан басқару және техникалық қызмет көрсету жүйесі арқылы біз әлем бойынша қашықтан қызмет көрсету мүмкіндігін ұсынамыз. Біз жылдам жауап береміз және сіздің әрбір қызмет сұранысыңызды уақтылы шешеміз.

Диагностикалық есеп

XINMAO қызмет инженерлері клиенттердің өндіріс және жабдықты техникалық қызмет көрсету процесіне кезең-кезеңімен қатысады, клиенттердің жабдықтарының жұмыс сапасы мен бар мәселелерін мұқият зерттейді, жабдықты объективті және бейтарап бағалайды, және негізделген әрі егжей-тегжейлі талдау есептері мен оңтайландыру ұсыныстарын ұсынады.

Технологияны жаңарту

Жабдықтың үздіксіз инновациясы мен дамуы, сондай-ақ жаңа технологиялар мен жаңа функциялардың қолданылуымен, XINMAO сізге жабдық технологиясының инновациясының қарқынын ұстануға көмектеседі, жабдықтарыңызды заманауи деңгейде ұстап тұруға тырысады, осылайша жоғары тиімділікке және төмен энергия тұтынуға қол жеткізеді.

Тұтынушы пайдасын арттыру шаралары:

Ең құнды жабдықты жаңарту жоспары

Соңғы технологиямен жабдықты трансформациялау бойынша ұсыныстар

Запас бөлшектерін басқару пакеті

Әрбір клиенттің сайттағы жабдық моделі үшін, қосалқы бөлшектердің әмбебаптығы мен тапсырыс бойынша жасалуының айырмашылығына және компонент проблемаларының жабдық жұмысына әсер ету дәрежесіне байланысты үш деңгейлі қосалқы бөлшектерді басқару жүзеге асырылады: жалпы бөлшектердің зауыттық қоймасы, тапсырыс бойынша бөлшектердің клиенттік қоймасы және маңызды бөлшектердің жеткізуші қоймасы. Болжамды қойма дайындау арқылы, жабдықты техникалық қызмет көрсету және жөндеу үшін қосалқы бөлшектерді алдын ала дайындауға болады, күтпеген тоқтап қалуды минимизациялау үшін. XINMAO әрбір клиентке қосалқы бөлшектердің қойма жоспарлауды дұрыс жасауға көмектесуге міндеттенеді.

4. Қашықтан басқару және техникалық қызмет көрсету

Қашықтан техникалық қызмет көрсету жабдықты пайдаланушы зауыты мен XINMAO арасында жабдық технологиясы, сенсорлық технология, бағдарламалық қамтамасыз ету және нақты уақыттағы байланыс технологиясы арасындағы өзара ынтымақтастық арқылы интеграцияланған басқаруды қалыптастырады.

Клиенттің пайдасы: Барлық тиісті байланыстардан жабдықтың жұмыс істеу деректерін алу

Үлкен деректер негізінде жабдықтың жұмыс сапасын талдау

Егер қашықтан мониторинг жабдығы аномалияларды көрсетсе, алдын алу шараларын уақытында қабылдауға болады

ITшешім

Жұмыс мониторингі модулі барлық желі деректерін нақты уақыт режимінде бақылауға жауапты және әрбір жеке құрылғының күйін де бақылайды. Мониторинг экраны арқылы әрбір құрылғының кейбір маңызды параметрлерін түсінуге болады: өндіріс жылдамдығы, өндіріс саны, жұмыс күйі, өндіріс параметрлері және кейбір жабдықтардың жоғалуы. Сондай-ақ, жабдықтың нақты уақыттағы дабылын көруге болады, бұл жеке құрылғының жұмысын тез түсінуге, орталықтандырылған басқаруды жүргізуге және ресурстарды ұтымды бөлуге мүмкіндік береді.

Энергияны басқару модулі өндіріс желісінің энергия көздерінің (электр, су, газ және т.б.) энергия тұтыну деректерін кешенді түрде жинайды, осылайша зауыттың жалпы энергия тұтынуы еш жерде жасырыла алмайды және бір көзбен көрінеді, бұл ұтымды басқару үшін мықты негіз береді.

Зияткерлік техникалық қызмет көрсету модулі клиенттерге бір құрылғы үшін техникалық қызмет көрсету қажет бөлшектердің санын алдын ала техникалық қызмет көрсету еске салу циклын орнату арқылы ескертеді, осылайша кәсіпорындар жабдықты жөндеу кезінде инвентаризацияны алдын ала дайындай алады және операторларға қазіргі уақытта техникалық қызмет көрсетуді қажет ететін жабдықты ескертеді, осылайша жабдықтың өмірлік циклін максималды түрде ұзартуға және кәсіпорын үшін қажетсіз қалдықтарды үнемдеуге мүмкіндік береді.

Есеп беру орталығы модулі клиенттердің қажеттіліктеріне сәйкес кесте форматында жобалауға мүмкіндік береді. Есептер өндірістік деректер есептері, дабыл есептері, энергия тұтыну есептері, техникалық қызмет көрсету басқару есептері және OEE есептеріне бөлінеді.

Басшылар үшін компьютер немесе мобильді телефон браузері арқылы олар жүйедегі есептер мен деректерге тікелей қол жеткізіп, кез келген уақытта зауыттың жағдайын бақылап отыра алады.

5. Оқыту жүйесі

XINMAO клиенттерге кешенді персоналдық техникалық оқыту бағдарламаларын ұсынуға міндеттенеді, оқыту арқылы жергілікті персоналдың дұрыс жұмыс істеуін қамтамасыз етеді, техникалық қызмет көрсету және ақауларды жою қабілеттерінің сапасын арттырады, тоқтап қалу уақытын минимизациялайды және жабдықтың тиімділігін жақсартады.

Біздің оқыту мазмұнымыз функционалдық құрылым принциптері, процесс процедуралары, іске қосу және техникалық қызмет көрсету сияқты бірнеше курстарды қамтиды және онлайн, жергілікті және сыртқы сияқты әртүрлі оқыту әдістерін ұсынады, сонымен қатар жергілікті қызметкерлердің қажеттіліктері, дағдылары мен нақты талаптарына сәйкес оқыту бағдарламаларын бейімдей алады.

Оқыту ресурстары

Әр түрлі оқыту әдістері клиенттерге өз жағдайларына сәйкес икемді таңдау жасауға мүмкіндік береді

Көп деңгейлі және бай оқыту материалдары клиенттердің нақты қажеттіліктеріне сәйкес оқытылуы мүмкін

Тәжірибелі дизайнерлер мен инженерлер оқытушы құрамымен бірігіп, жоғары сапалы оқыту нәтижелерін жасайды

"Жекелендірілген оқыту" XINMAO оқыту инженерлері мен зауыт менеджерлері анықтаған дәл және жеке оқыту мазмұны арқылы现场 операциялық команда қызметкерлерінің дағдыларын жылдам жақсартуды қамтамасыз ете алады.

XINMAO клиенттерге кешенді шешімдер ұсынуға міндеттенеді, клиенттердің қызметкерлерінің техникалық мүмкіндіктерін жақсартуға көмектесуді мақсат етеді. Ол тәжірибелі қызмет көрсету инженерлерін клиенттердің сайттарын уақытында тексеруге жібереді, қызметкерлердің техникалық мүмкіндіктерін бағалайды және бағалауға негізделген шешімдер (оқыту) жоспарларын әзірлейді.

Жауабым

Жауабым2024-09-08

2024-09-21

2024-09-26