SOLUTION FOR CSD

Welcome to XINMAO, your premier provider of comprehensive bottling solutions for carbonated soft drinks.

Whether you are looking to bottle your products in PET, glass, or cans,our advanced technology and expertise ensure the highest quality and efficiency in your production process.

| Application | Carbonated drinks,soft drinks,gas water,sparkling water,soda water,energy drinks,kvass |

| Type | PET Bottle, Tin Can, Glass Bottle |

| Filling system | Isobaric |

| Filling speed | 1000-36,000BPH (500ml)(Customized) |

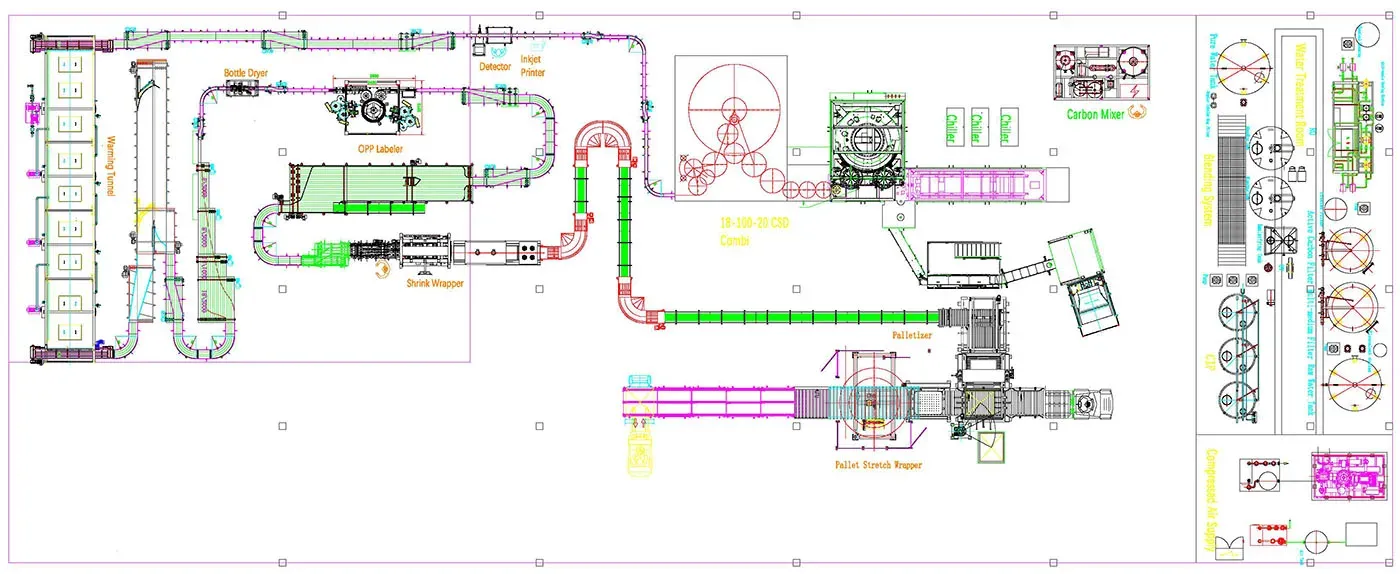

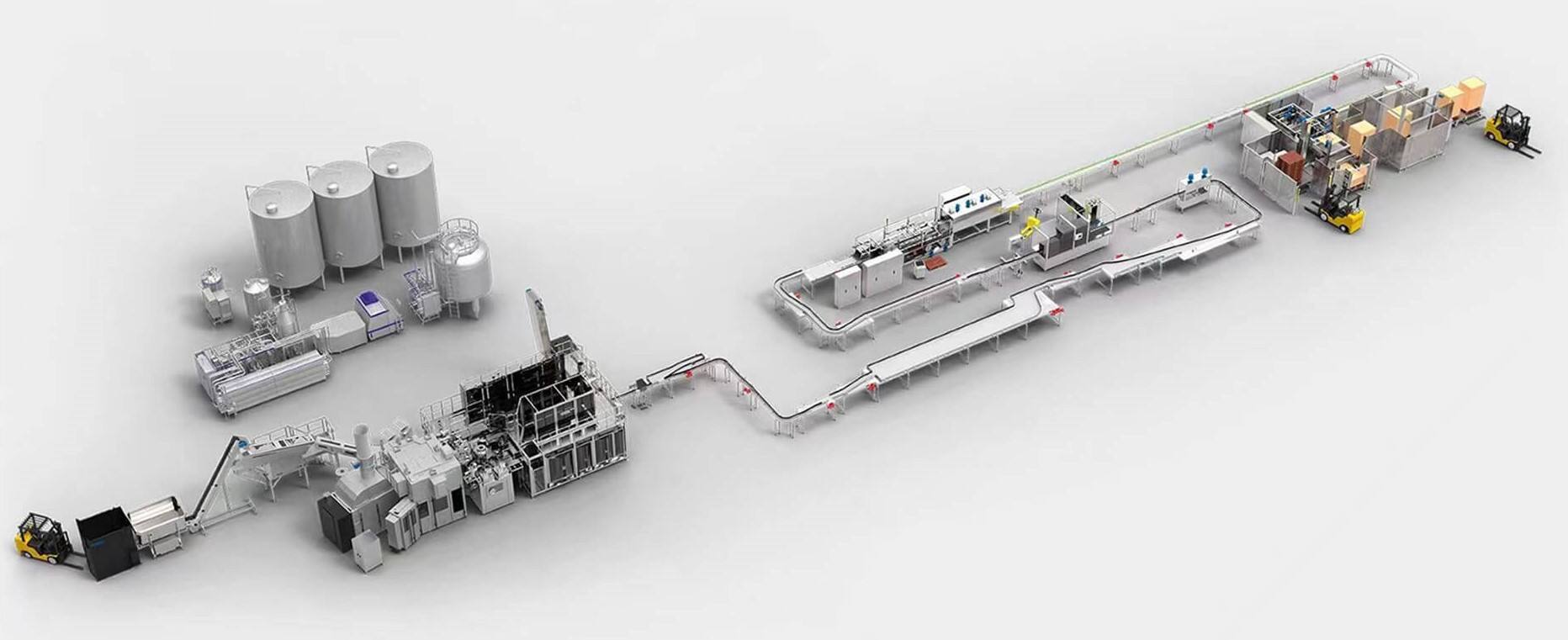

Comprehensive One-stop Carbonated Soft Drinks Bottling Solutions

At XINMAO, we offer a full range of bottling solutions tailored to the unique needs of carbonated soft drink manufacturers.

Our systems cover every aspect of the bottling process, providing you with a seamless, integrated solution.

| PET Bottled Carbonated Soft Drinks Bottling | Our PET bottling lines are designed for high-speed production and reliability. With capacities up to 36,000BPH (500ml), our systems handle various bottle sizes and shapes, ensuring flexibility and efficiency in your production process. |

| Glass Bottled Carbonated Soft Drinks Bottling | Our glass bottling lines are equipped with advanced technologies to ensure precise filling, capping, labeling and packaging. We provide solutions that maintain the integrity and quality of your beverage while enhancing the shelf appeal of your product. |

| Can Carbonated Soft Drinks Bottling | Cans are a popular choice for carbonated soft drinks due to their durability and convenience. Xinmao's canning lines are designed for customized production volumes with precise filling and sealing capabilities to ensure your beverages are canned efficiently while maintaining their freshness and carbonation. |

Why Choose XINMAO

XINMAO is your premier provider of advanced water bottling solutions.

Our cutting-edge technology and industry expertise ensure that we deliver efficient,high-quality bottling systems tailored to meet your customized needs.

| Global Reach and Success | XINMAO has successful experience in cooperation with customers in the global markets of Middle East, Africa, Southeast Asia, South America, North America, Oceania, Asia, Europe. Our global experience makes us a trusted partner in the water bottling industry. |

| Expertise and Innovation | With over 20 years of experience in the beverage filling industry,Xinmao is at the forefront of innovation in water bottling technology.Our team of experts continuously develops and implements cutting-edge solutions to keep you ahead of the competition. |

| Customized Solutions | Every customer has customized needs,Xinmao can tailor-make bottling solutions according to your specific requirements.Our professional team works closely with you to design and implement a system that suits your production goals and budget. |

| Quality and Reliability | We are committed to delivering high-quality,reliable bottling systems.Our equipment is built to last,ensuring long-term performance and durability.With XINMAO,you can trust that your production line will run smoothly and efficiently. |

|

Comprehensive After-sales |

From initial consultation and design to installation and maintenance,Xinmao provides comprehensive technical support throughout your project life cycle.Our professional team is always available to help you ensure that your production line runs smoothly and achieves greater benefits. |

Water Treatment

Water purification system can effectively get rid of muddy organic, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of micro-organism and some of height-metal ion in the raw water resource. It can also reduce hardness of water to make it all specifications of the water quality fully meet the state fresh drinking water standards, even standard of healthy mineral water.

Purify Process:

Raw water>Water pump>Silica sand filter>Active carbon filter>Sodium ion exchanger>High pressure pump>Reverse osmosis>Ozone generator>Water tank>Pure water

Bottle Blowing Machine

Automatic PET Bottle Blowing Machine is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing water bottles, soda bottles, cola bottles. Bottle shapes are all customized and can be adjusted according to your requirements.

Blowing process:

1) Preform inlet controlling

2) Bottle preform heating controlling

3) Blowing technology controlling

4) Bottle check and outlet

Mix System

Carbonated beverages are mainly composed of water, syrup and carbon dioxide. The syrup is made through sugar melting pots and mixing tanks. After filtering, it is pumped into the syrup tank in the carbonated beverage mixer. At the same time, the sterilized product water is also pumped into the beverage mixer. The water tank is vacuum degassed to facilitate the mixing of carbon dioxide. Through the proportioning system on the beverage mixer, the water and syrup are mixed in proportion to achieve the desired taste. Under the action of controlling the appropriate pressure, the carbon dioxide is dissolved into the material. , it can be made into carbonated beverages with ideal air-locking capacity.

Filling System

XINMAO DCGF-series rinsing, filling, Capping 3-in-1 monobloc machine introduced by foreign advanced gas-filling technique is a high performance fully automatic liquid packaging equipment. Machine for carbonated beverage packaging machine has the following characteristics: filling tank, filling valves and other components in direct contact with the material are high-quality stainless steel or non-toxic materials, in line with food hygiene requirements: use of resistant seals hot rubber to meet the high-temperature sterilization process of user requirements: PCL programmable controller used to realize from the bottle into the machine to the packaging of finished using the automatic control of frequency control, easy to transfer the user to adjust prepared to meet the different process on the capacity requirements; using isobaric filling principle and popular spring-loaded valves, ensuring the quality of the beverage, using an advanced magnetic clutch adjustment screw cap torque device to ensure the quality of the blocks.

Labeling Machine

We offer several different types bottle labeling machine based on your requirement. Machines can be used for PVC sleeve label, self-adhesive label, OPP/BOPP label.

Sticker labeling machine:

After the bottle-separating mechanism separates the products, the sensor detects the passing of the product and sends a signal back to the labeling control system. The control system controls the motor to send out the label and attach it to the position where the product is to be labelled. The product flows through the labeling device and the labeling tape Drive the product to rotate, the label is rolled over, and the sticking action of a label is completed.

PVC labeling machine:

When a bottle on the conveyor belt passes through the bottle detection eye, the servo-controlled drive group will automatically send a label, and the brushing wheel group will brush the next label, and the label will be sleeved on the bottle.

OPP labeling machine:

Is used in continuous roll label sticking on bottles by hot glue. It uses local glue spraying method. It consumes less glue and has low running cost. The maximum speed is 600BPM, which is mainly suitable for high-level drinking water and soft drink.,etc production.OPP labeling machine working more high speed and quiet, low glue consumption, compare with shrink label, its lower cost in material.

Packing System

The biggest advantage of Xinmao's film packaging machine is that the cutter is of very good quality and will not break even after many years of use. Foreign famous brands also use this configuration.

The cutter of the film packaging machine with general configuration cannot cut after a few years, and the film sticks and the sealing is not good. In addition, it is very expensive to replace a cutter, which increases the cost of the enterprise. However, our cutter will never have this problem.

This packing machine combines a classic, user-friendly design with advanced features like "bottles vibration" technology to prevent squeezing. Its extended conveyor and host length improve bottle sorting and overall performance.

With over 90% high-quality imported electrical components and a history of stability, it's a top choice for automatic film packing.