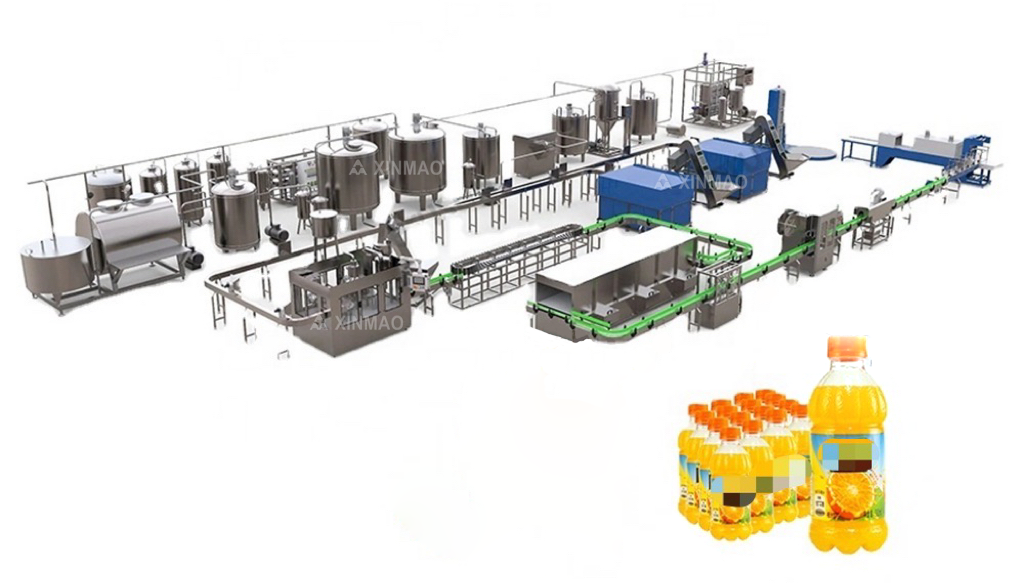

SOLUTION FOR JUICE

Welcome to XINMAO, your leading provider of comprehensive juice bottling solutions.

Whether you're looking to bottle juice in PET, glass, or cans, our advanced technology and expertise ensure that you receive the highest quality and efficiency in your production process.

| Application | Juice, tea, energy drinks, vitamin drinks, functional beverage |

| Type | PET Bottle, Glass Bottle, Aluminum Can |

| Filling system | 85℃ Hotfill,60-70℃ normal temperature filling |

| Filling speed | 1000-36,000BPH (500ml)(Customized) |

Comprehensive One-stop Juice Bottling Solutions

At XINMAO, we offer a complete range of juice bottling solutions designed to meet the diverse needs of the beverage industry.

Our systems cover every aspect of the bottling process, providing you with a seamless, integrated solution.

| PET Bottled Juice Bottling | Our PET bottling lines are designed for high-speed production and reliability. With capacities up to 36,000BPH (500ml), our systems handle various bottle sizes and shapes, ensuring flexibility and efficiency in your production process. |

| Glass Bottle Juice Bottling | Glass bottles provide your juice products with a premium look and feel. Our glass bottling lines are equipped with advanced technologies to ensure precise filling, capping, labeling and packaging. We provide solutions that maintain the integrity and quality of your juice while enhancing its shelf appeal, greatly increasing your bottom line. |

| Can Juice Bottling | Canning is a popular choice for juice products due to its durability and convenience. Our canning lines can be customized to meet different customer needs and feature precise filling and sealing capabilities. We ensure your juice is canned efficiently, preserving its freshness and taste. |

Why Choose XINMAO

XINMAO is your premier provider of advanced water bottling solutions.

Our cutting-edge technology and industry expertise ensure that we deliver efficient,high-quality bottling systems tailored to meet your customized needs.

| Global Reach and Success | XINMAO has successful experience in cooperation with customers in the global markets of Middle East,Africa,Southeast Asia,South America,North America,Oceania,Asia,Europe. Our global experience makes us a trusted partner in the water bottling industry. |

| Expertise and Innovation | With over 20 years of experience in the beverage filling industry,Xinmao is at the forefront of innovation in water bottling technology.Our team of experts continuously develops and implements cutting-edge solutions to keep you ahead of the competition. |

| Customized Solutions | Every customer has customized needs,Xinmao can tailor-make bottling solutions according to your specific requirements.Our professional team works closely with you to design and implement a system that suits your production goals and budget. |

| Quality and Reliability | We are committed to delivering high-quality,reliable bottling systems.Our equipment is built to last,ensuring long-term performance and durability.With XINMAO,you can trust that your production line will run smoothly and efficiently. |

|

Comprehensive After-sales Service Support |

From initial consultation and design to installation and maintenance,Xinmao provides comprehensive technical support throughout your project life cycle.Our professional team is always available to help you ensure that your production line runs smoothly and achieves greater benefits. |

Water Treatment

Water purification system can effectively get rid of muddy organic, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of micro-organism and some of height-metal ion in the raw water resource. It can also reduce hardness of water to make it all specifications of the water quality fully meet the state fresh drinking water standards, even standard of healthy mineral water.

Purify Process:

Raw water>Water pump>Silica sand filter>Active carbon filter>Sodium ion exchanger>High pressure pump>Reverse osmosis>Ozone generator>Water tank>Pure water

Blow Molding Machine

Automatic PET Bottle Blowing Machine is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing water bottles, soda bottles, cola bottles. Bottle shapes are all customized and can be adjusted according to your requirements.

Blowing process:

1) Preform inlet controlling

2) Bottle preform heating controlling

3) Blowing technology controlling

4) Bottle check and outlet

Juice Processing

Complete juice processing system with reasonable mixing and sterilization technology, not only can be suitable for common products, but also can satisfy special requirements of customers, for example juice, milk, cream or high viscosity products containing fiber and large pulp granules.

UHT System

Warming, Pasteurizing & Cooling Tunnel is being manufactured to provide a suitable thermal process to comply with beverage processing requirements and to achieve optimum product quality, lasting shelf life and appearance of your filled product

The product has 3 main applications:

Tunnel Warmer:

For product warming, tempering or slow heat up process to ensure ZERO product breakage. Tunnel Pasteurizer:

Applied to product to ensure that the pasteurizing process is complete. Usually implemented when the filling process has not allowed suitable time for effective pasteurizing to take effect.

Tunnel Cooler:

After the hot fill product and pasteurizing, fast, effective product cooling is required in order to maintain the product color, smell, taste, texture, appearance and other important characteristics that are important to your products market potential.

Filling System

Reasonable machine structure

Much higher output

High-efficiency rinsing-nozzles;

Corrosion-resistant bearings from NSK or SKF;

Mechanical valve filling, flow meter filling, weighing filling or laser positioning filling for choice;

Open design for gear transmission;

Siemens PLC & Danfoss VFD & ABB Main motor;

French "ZALKIN" capping technology is used forhigher performance;

Finest bench-working in Chinese Packaging Machinery Industry

Labeling Machine

We offer several different types bottle labeling machine based on your requirement.

PVC labeling machine:

When a bottle on the conveyor belt passes through the bottle detection eye, the servo-controlled drive group will automatically send a label, and the brushing wheel group will brush the next label, and the label will be sleeved on the bottle.

OPP labeling machine:

After the container is fixed, the container starts to rotate according to the set way.When the container reaches the detection position of the electric eye, the computer host controls the label feeding system to send the label. When a label feeding action is completed, the label is separated from the backing paper and attached to the product.

Sticker labeling machine:

The sensor detects the passing of the product and sends a signal back to the labeling control system. The control system controls the motor to send out the label and attach it to the position. The product flows through the labeling device and the labeling tape Drive the product to rotate, and the sticking action of a label is completed.

Packing System

The biggest advantage of Xinmao's film packaging machine is that the cutter is of very good quality and will not break even after many years of use. Foreign famous brands also use this configuration.

The cutter of the film packaging machine with general configuration cannot cut after a few years, and the film sticks and the sealing is not good. In addition, it is very expensive to replace a cutter, which increases the cost of the enterprise. However, our cutter will never have this problem.

This packing machine combines a classic, user-friendly design with advanced features like "bottles vibration" technology to prevent squeezing. Its extended conveyor and host length improve bottle sorting and overall performance.

With over 90% high-quality imported electrical components and a history of stability, it's a top choice for automatic film packing.