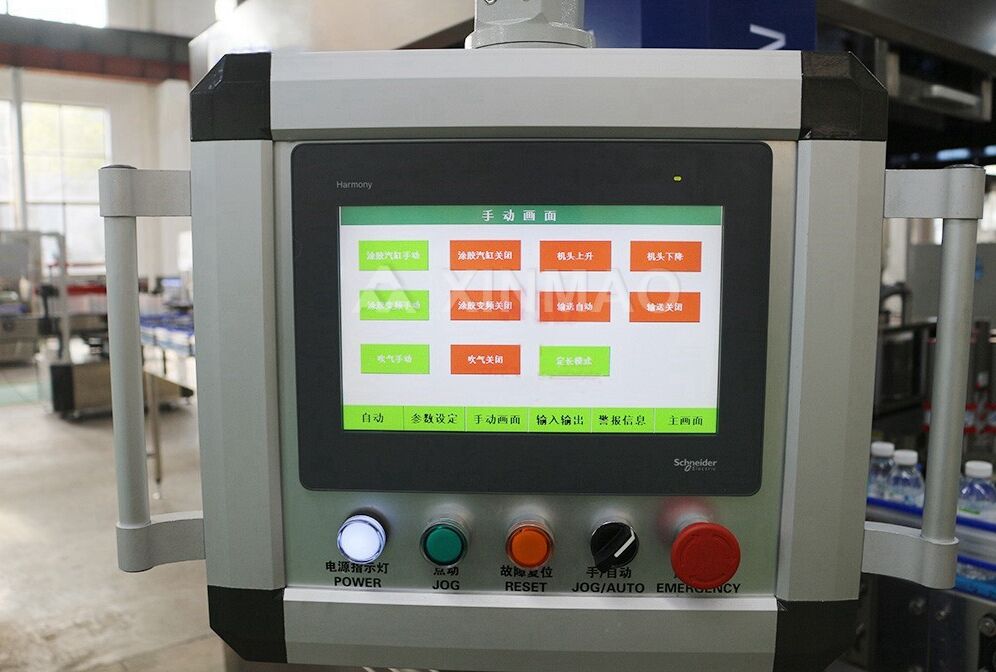

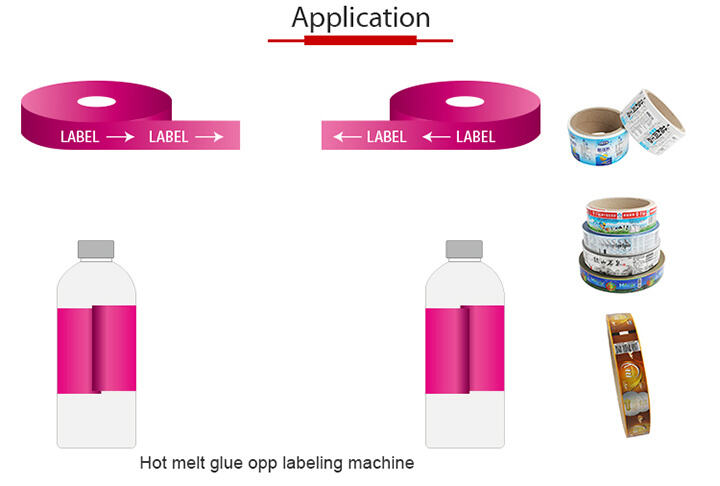

Машина для маркировки горячим расплавом XINMAO подходит для нанесения OPP-этикеток на всю окружность PET, PP, PE круглых и квадратных бутылок с минеральной/чистой водой, напитками, молоком, моющими средствами и т.д. Материал поставляется в рулонах из OPP, бумаги, бумажно-пластикового композитного материала, подходящего для точной маркировки при различных скоростях и высоких скоростях; централизованная система подачи и возврата горячего клея, минимальные потери этикеток и расход клея; красивый узор клея, подходящий для прозрачных этикеток. Автоматическое логическое программное управление, интерфейс «человек-машина», простая эксплуатация и легкое обслуживание.

Этикетировочная машина с термоклеем подходит для маркировки OPP по всей окружности круглых и квадратных бутылок из PET, PP, PE с минеральной/чистой водой, напитками, молоком, моющими средствами и т. д. Материалом для подачи служит рулонный OPP, бумага, композитный материал из бумаги и пластика, подходящий для точной маркировки на различных скоростях и высоких скоростях; централизованная система подачи и возврата термоклея, небольшие потери этикеток и расход клея; красивый рисунок клея, подходящий для прозрачной этикеточной бумаги. Автоматическое управление программой логики, интерфейс человек-машина, простота эксплуатации и обслуживания.

1). Принять способ маркировки колес;

2). Этикетка передается через этикетировочное колесо, движется по направляющей и управляет этикетировочной работой;

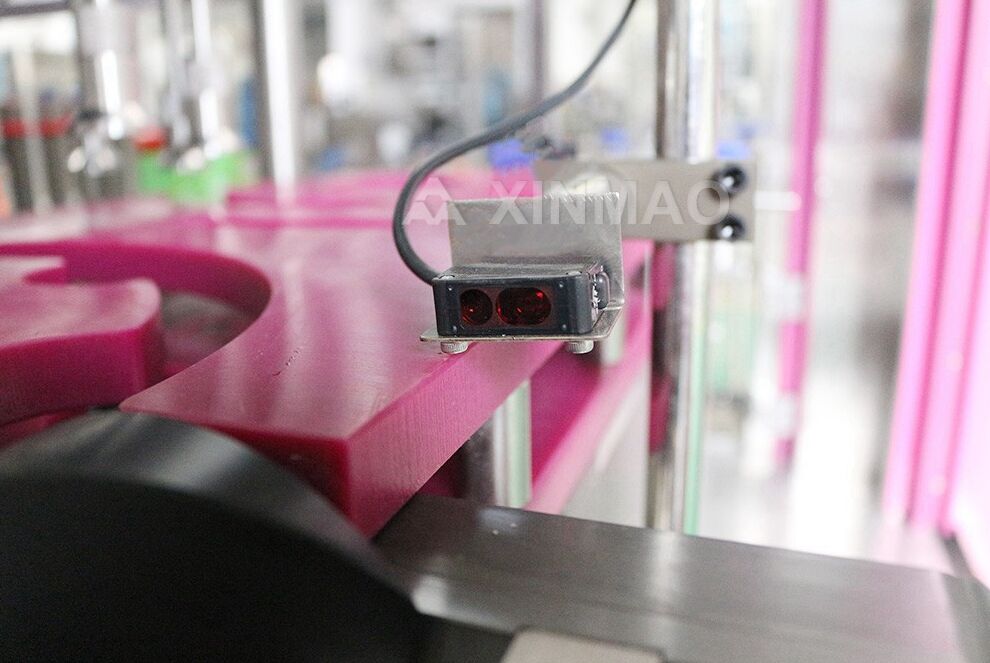

3). Когда метка проходит через назначенное колесо, датчик автоматически обнаруживает I-Mark;

4). После подтверждения положения электронного глаза демодулятор автоматически отрегулирует скорость колеса, а затем точно назначит положение резки этикетки;

5). Этикетка проходит через колеса, а затем поступает в режущую часть для выполнения работы по резке этикетки, отрезанная этикетка будет отправлена в цилиндр вакуумного захвата;

6). Контейнеры, перемещаемые конвейерной лентой, будут правильно размещены с помощью звездочки, затем этикетка, на которую нанесен клей, перейдет к первой этикетировке в зоне ролика, и, наконец, синхронный ремень выполнит последнюю операцию этикетирования.

| Машина для нанесения этикеток на горячий клей | ||

| Нет | Товар | Параметры данных |

| 1 | Напряжение | 380В |

| 2 | Частота | 50Гц |

| 3 | Мощность | 8КВт |

| 4 | Доступные размеры бутылки | Диаметр:40-105мм, |

| высота=80-350MM | ||

| 5 | Спецификация этикетки | Длина: 125-325 мм, |

| Высота: 20-150 мм | ||

| 6 | Способ наклеивания | Рулонная окраска (около 10 мм, как этикетка сверху, так и снизу) |

| 7 | Вместимость | 9000-36000 бутылок в час |

| (бутылка 500 мл) | ||

| 8 | Расход клея | л кг/ 100,000 болтов |

| (высота этикетки:50мм) | ||

| 9 | Давление сжатого воздуха | МИН5.0бар МАКС8.0бар |

| 10 | Потребление сжатого воздуха | 0,2 м³/минуту |

| 11 | Общие размеры | 2500КГ |

| 12 | Общий вес | Д=3150,Ш=1770,В=1800 |

| Основная конфигурация | |

| Сенсорный экран | Сименс |

| ПЛК | |

| Преобразователь частоты | |

| Материал клапана наполнения | Нержавеющая сталь 304/316 |

| Пневматические компоненты | Фесто |

| Переменчик фотоэлементов | Больной |

| Датчик приближения | Больной |

| Двигатель | СИУ |