Welcome to XINMAO, your leading provider of comprehensive can bottling solutions.

XINMAO Packaging highly values production flexibility and overall efficiency in the production of can drink production lines.

Type Tin Can, Aluminum Can, Plastic Can

Filling system Isobaric filling、normal pressure

Filling speed 1000-36,000BPH (330ml)(Customized)

Application Juice, tea, energy drinks, vitamin drinks, functional beverage, carbonated drinks, soft drinks, sparkling water, soda water, mineral water, pure water, still water, RO water, drinking water, Beer, carbonated alcoholic drinks, liquor,dairy beverages,milk

It is suitable for filling and capping aluminum canned beverage, such as water, beer, CSD, etc. It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system. It is the preferred equipment for the medium beer and beverage plant.

1.Water Treatment

Water purification system can effectively get rid of muddy organic, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of micro-organism and some of height-metal ion in the raw water resource. It can also reduce hardness of water to make it all specifications of the water quality fully meet the state fresh drinking water standards, even standard of healthy mineral water.

Purify Process:

Raw water>Water pump>Silica sand filter>Active carbon filter>Sodium ion exchanger>High pressure pump>Reverse osmosis>Ozone generator>Water tank>Pure water

2.Mix System

Option 1: Juice mixing

The juice mixing system formulates the production process according to the characteristics of different kinds of juice. According to the formula of the juice beverage, the juice preparation process is designed.

Option 2: Carbonated drink mixing

Carbonated beverages are mainly composed of water, syrup and carbon dioxide. The syrup is made through sugar melting pots and mixing tanks. After filtering, it is pumped into the syrup tank in the carbonated beverage mixer. At the same time, the sterilized product water is also pumped into the beverage mixer. The water tank is vacuum degassed to facilitate the mixing of carbon dioxide. Through the proportioning system on the beverage mixer, the water and syrup are mixed in proportion to achieve the desired taste. Under the action of controlling the appropriate pressure, the carbon dioxide is dissolved into the material. , it can be made into carbonated beverages with ideal air-locking capacity.

3.Carbonator

Blending tanks are widely used in soft drink, juice, dairy, and other beverage industries. They are used for blending and mixing various kinds of materials, and materials are mixed evenly by stirring. It is an indispensable equipment for manufacturers of beverages, dairy products, and pharmaceuticals.

All materials like concentrate, syrup, water...will be added into this tank, and stirred evenly. This machine equips with liquid level gauge, air respirator, CIP cleaning port, sanitary manhole...etc.

4.Can De-Palletizer

The depalletizer is mainly used in the unloading of tinplate cans and aluminum cans. The empty cans stacked on the pallet are pushed to the mesh conveyor layer by layer from top to bottom. The unloading of cans and aluminum cans is automatically controlled by PLC programmable computer. The depalletizer adopts frequency conversion motor, frequency conversion speed regulation, computer control, and the conveying is stable, smooth and reliable; automatic control technology, mechatronics technology, network technology, computer-controlled automatic operation. The reciprocating cycle automatic stacking meets the set requirements.

Replacing manual tank discharge and traditional empty tank unloader can save a lot of labor and improve production capacity. The programmable computer control system is adopted to improve the accuracy of the mechanical action, and the operation is easy. The pallet lifting table is self-locking and lifting, and the pallet stacking machine adopts cylinder lifting.

5.Twist Rinser

The can twist rinse system links the depalletiser to the canning machine. The cans, through gravity, complete a full 360° turn enabling the water rinse system or ionised air (optional extra) to clean the interior of the cans as they descend through the twist. This process is vital to ensure any debris from the manufacturing process or during storage is removed prior to filling.The second point is conducive to printing the bottom of the can. After printing, use the flip auger to turn it over again.

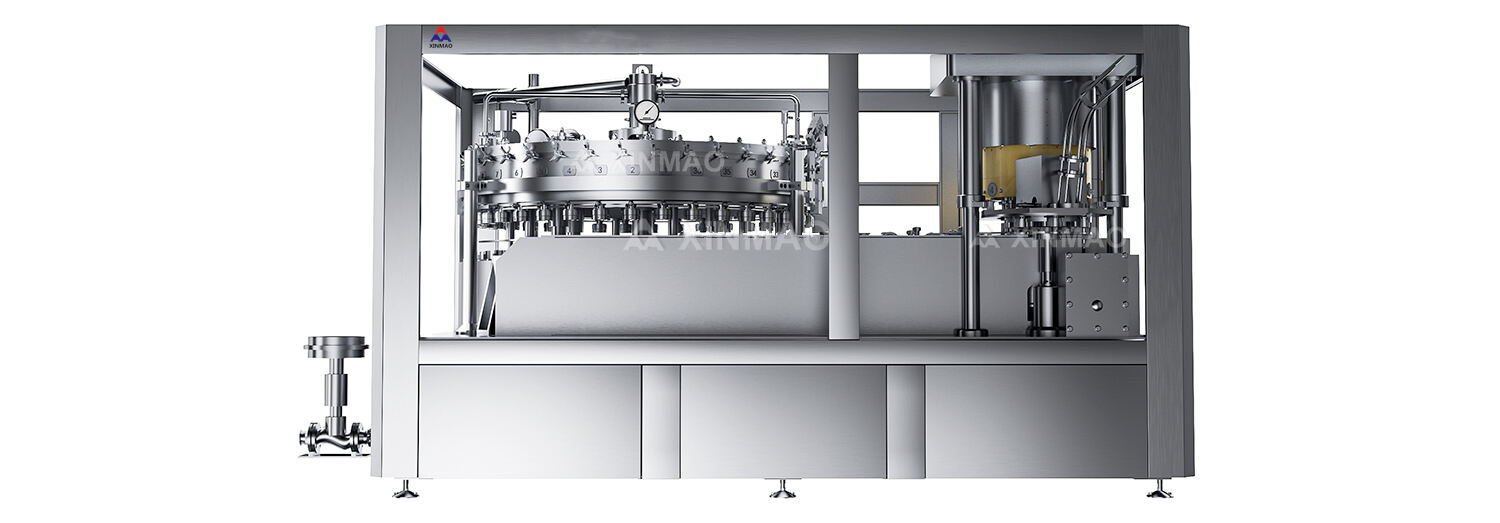

6.Filling & Seaming System

It is mainly used for continuous cleaning of pop-top cans, and is also suitable for other types of tinplate cans with similar size and shape. It has the characteristics of good cleaning effect, reasonable structure, balanced work and high production efficiency.

It adopts the principle of isobaric filling, and the filling valve adopts mechanical valve, which has fast filling speed and high liquid level accuracy; it has a perfect CIP cleaning function. The combination of the guide device on the filling valve mouth and the lifting device at the bottom of the dragging bottle can accurately seal the bottle mouth and the filling valve and reduce the leakage of materials from the can mouth. Bottles, no dripping, easy operation and maintenance, etc.

The capping part seals the caps to the cans that have been filled with products, and is sent to the subsequent process by the conveyor chain.

| Model | Production capacity (cans/hour) |

| DGF12-1 | 1000-1500 |

| DGF12-4 | 2000-3000 |

| DGF20-4 | 4000-6000 |

| DGF24-4 | 6000 - 10000 |

| DGF36-6 | 8000 - 15000 |

| DGF48-8 | 10000 - 20000 |

Can washing machine

Can filling machine

Can capping machine

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |

7.Pasteurizing Tunnel

The Warming, Pasteurizing & Cooling Tunnel is being manufactured to provide a suitable thermal process to comply with beverage processing requirements and to achieve optimum product quality, lasting shelf life and appearance of your filled product

The product has 3 main applications:

Tunnel Warmer:

For product warming, tempering or slow heat up process to ensure ZERO product breakage. Tunnel Pasteurizer:

Applied to product to ensure that the pasteurizing process is complete. Usually implemented when the filling process has not allowed suitable time for effective pasteurizing to take effect.

Tunnel Cooler:

After the hot fill product and pasteurizing, fast, effective product cooling is required in order to maintain the product color, smell, taste, texture, appearance and other important characteristics that are important to your products market potential.

8.Packing System

We have Shrink wrapping machine and Case packing machine for you to choose.

PE Film Packaging Machine:

Put the package directly on the chain plate for transportation, and the package passing through the sealing and tangent line is pressed by the pressing device set above to prevent it from falling. After the ejection cylinder exits, the film sealing cylinder and the film cutting cylinder work at the same time to complete the film sealing. After the filming is completed, the package enters the shrink furnace to shrink. After the packaging has been shrunk, it enters the auxiliary rack, and is stacked after the cooling device is installed at the end.

Case Packaging Machine:

The bottles are separated into multiple lanes on the conveyor belt, the bottles are grouped and dropped onto the cardboard by the bottle drop break. During bottle drop break and cardboard drop, pass through a set of template blocks and then fold the cardboard into a carton form.