The two-step Pet stretch blow moulding machine which are applicable in a wide range of PET packaging practice, such as for beverages, edible oil, food, pharmaceutical products and cosmetics,etc. With more than 10 years experience in developing and producing blow molding machine as well as the advanced technology absorbed domestic and abroad, we have developed with our constant innovation dozens of high speed and high precision equipments which have won the top reputation in the filed.

This fully-automatic bottle blowing machine is a linear bottle blowing machine which is developed and researched by the most advanced bottom making technology in the current world and molded through blowing PET(Polyethylene Terepthalate)by high pressure compressed gas.The machine needs a bottle blank appropriate to bottle type.This linear bottle blowing machine can be used independently for blowing botles or completion of bottle blowing before filling lines.The machine shows characteristics such as high intelligence,stable and reliable mechanical performance, high production efficiency,low cost and pollution free from intermediate process,it is widely used for production of food,drink,cosmetic vessel.

| Model | XM-K4 | |

| Bottle type specification | Cavity | 4 |

| Max.volume | 2L | |

| Bottle mouth maximum overall diameter | 25-29mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximum height | 330mm | |

| Capacity specification | Theory output | 8000-10000BPH |

| Bottle type volume | 600ML | |

| Bottle type weight | 13.5g | |

| Bottle type | Round | |

| Power specification | Light tube quantity | 32pcs |

| Light tube power | 2KW/3KW | |

| Maximum heating power | 76KW | |

| All electric machine installation | 99.59KW | |

| Actual consumption | 40KW | |

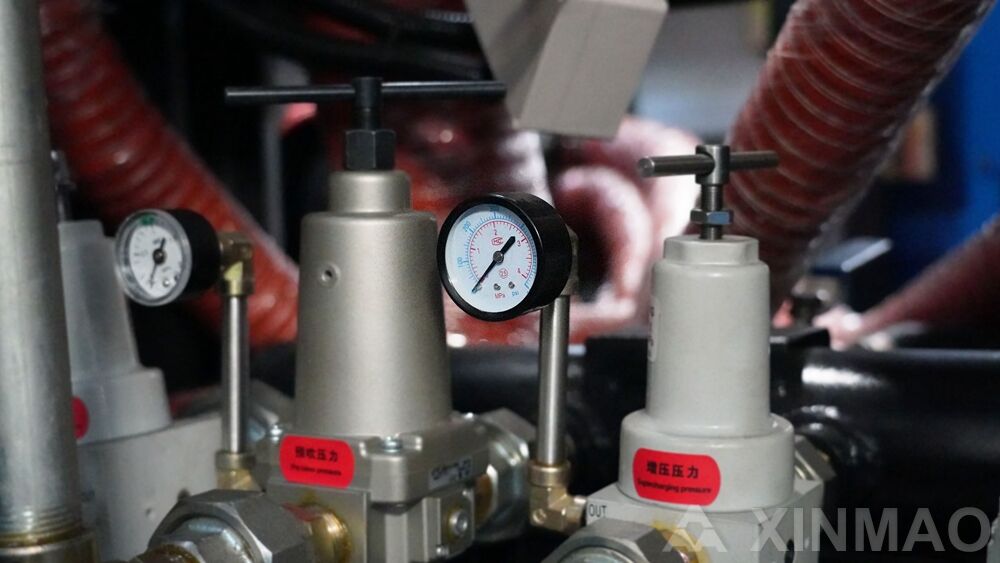

| Air pressure specification | Work pressure | 5-6kg/cm2 |

| Blow bottle pressure | 25-45kg/cm2 | |

| Higher -pressure air consumption | 6000Ltr/min | |

| Frozen water specification | Work pressure | 5-6 kg/cm2 |

| Temperature range | 10℃ | |

| Consumption | 8000kcal/hr | |

| Frozen water flow | 120L/min | |

| Machine specification | Machine size | 4.538x2x2.38 |

| Machine weight | 7ton | |

1.6、Heating has two groups of relatively independent far-infrared lamp ovens, each group of far-infrared lamp can be adjusted in the longitudinal direction according to the different bottle blanks.

1.7、Bottles are heated, and while the bottles are rotating to make them evenly heated, the bottle mouth is cooled, and then the fan blows hot air on the bottles to make the inner and outer walls of the bottles evenly heated.

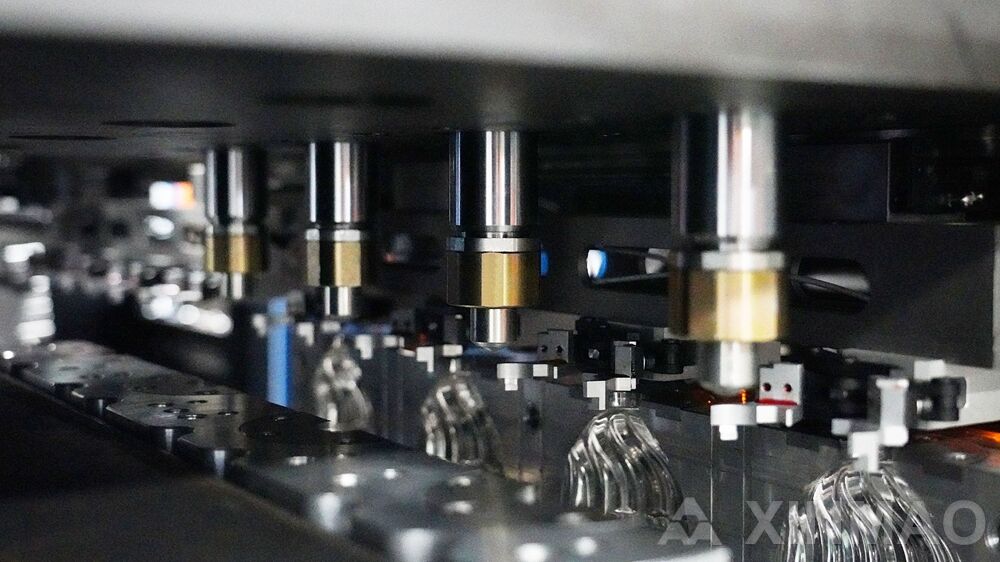

1.8、After the bottle billet enters the blowing mold, the pre-blowing air enters to circumferentially stretch the blowing bottle billet; when the stretching bar reaches the bottom of the mold, the high-pressure air enters the mold cavity to further stretch the bottle billet, so that the bottle wall is close to the mold jig.

1.9. High-pressure air is kept in the mold for a certain period of time to eliminate the internal pressure caused by the

stretching of the bottle blank on the one hand.On the other hand, it makes the bottle wall tighten against the mold wall in order to improve the crystallinity of the bottle plastic.

1.10、High-pressure gas starts to exhaust and demold at the end of the process.

1.11、Bottle blowing process is finished.

1.12、Bottles are transferred to the lower bottle station through the chain plate, where they are plucked up by the lower bottle cylinder and then blown out by the airflow.

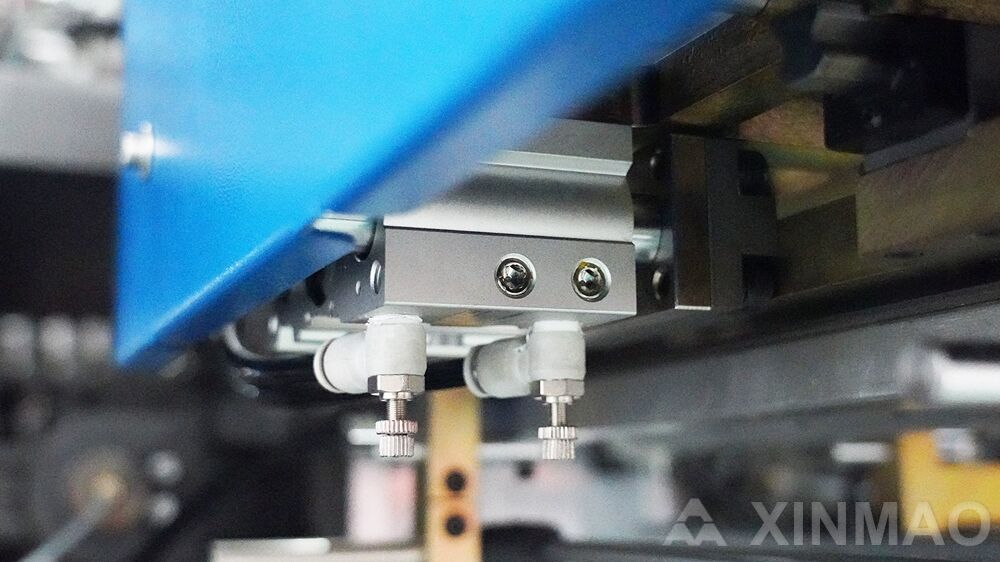

Acting cylinder

Bottle out air conveyor

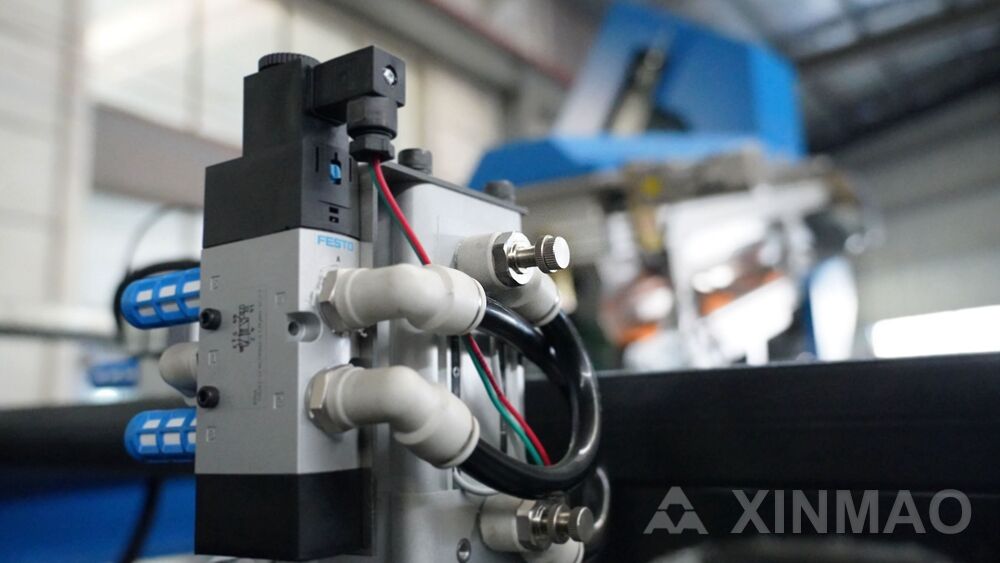

Electromagnetic valve

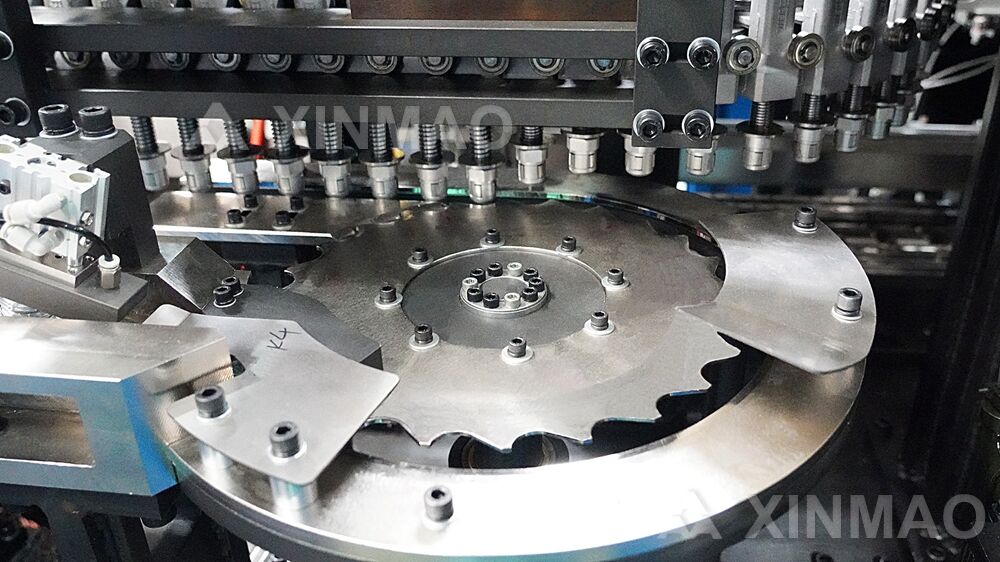

Mould

Mould

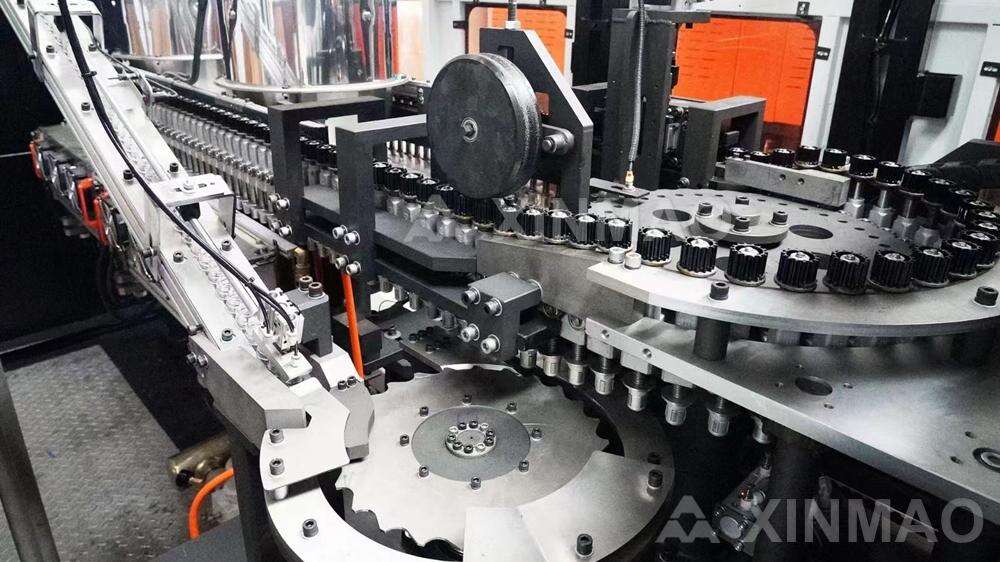

Preform heating oven

Preform loading drive plate

Preform pressing wheel

Preform slide rail

Pressure reducing valve

Sealing head

Sewage outlet

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |