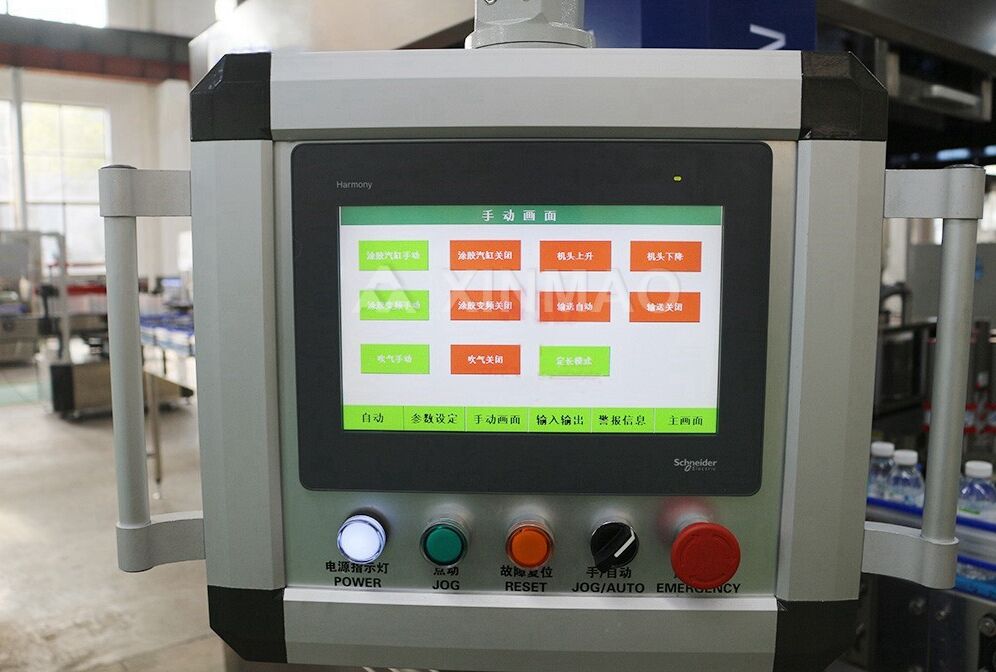

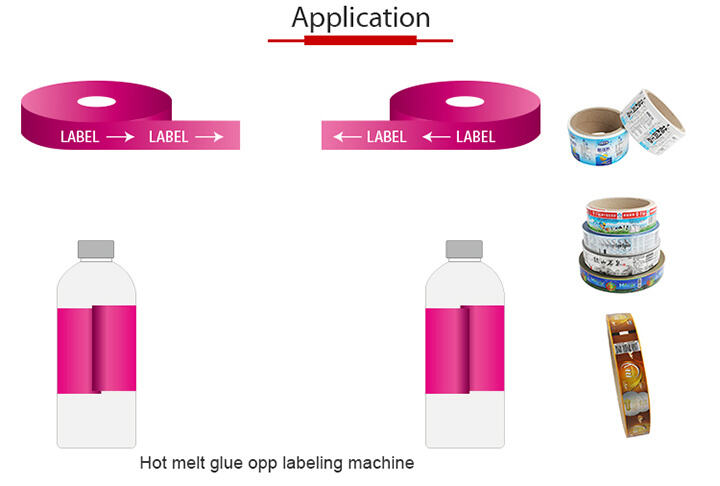

XINMAO hot melt glue labeling machine is suitable for OPP full circumference labeling of PET, PP, PE round and square bottles of mineral/Pure water, beverage, milk, detergent, etc. The supply material is rolled OPP, paper, paper-plastic composite material, suitable for accurate labeling at various speeds and high speeds; centralized hot melt glue supply and return glue system, small label loss and glue consumption; beautiful glue pattern, suitable for transparent label paper. Automatic logic program control, human-machine interface, simple operation and easy maintenance.

Hot melt glue labeling machine is suitable for OPP full circumference labeling of PET, PP, PE round and square bottles of mineral/Pure water, beverage, milk, detergent, etc. The supply material is rolled OPP, paper, paper-plastic composite material, suitable for accurate labeling at various speeds and high speeds; centralized hot melt glue supply and return glue system, small label loss and glue consumption; beautiful glue pattern, suitable for transparent label paper. Automatic logic program control, human-machine interface, simple operation and easy maintenance.

1). Adopt wheel labeling way;

2). Label transmit via label wheel, run along the guide rail and operate the labeling work;

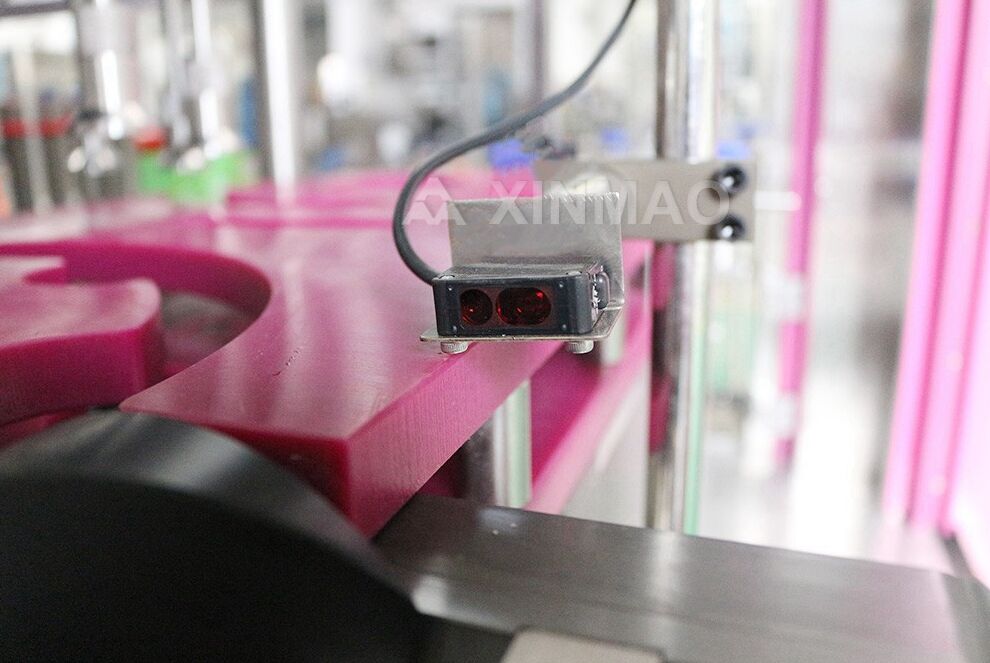

3). When the label through the appointed wheel, the sensor will automatically detect I-Mark;

4).Once confirms the electronic eye position, the demodulator will automatically adjustment the speed of wheel, and then appoints the label cutting position accurately;

5).The label through the wheels and then enter into the cutting part to carry out the label cutting work, the label cut will be send to the vacuum-grip cylinder;

6). The containers which is transmitted by conveyor belt will be arranged properly via star wheel, then, the label which has been painted with glue will proceed the first labeling in the roller area, last, rely on the synchronous belt to proceed the last labeling operation.

| Hot glue opp labeling machine | ||

| NO | Item | Parameter data |

| 1 | Voltage | 380V |

| 2 | Frequency | 50Hz |

| 3 | Power | 8KW |

| 4 | Available bottle dimension | Diameter:40-105mm, |

| height=80-350MM | ||

| 5 | Label specification | Length:125-325mm, |

| Height:20-150mm | ||

| 6 | Gluing way | Roll painting(about 10mm, both label head and tail) |

| 7 | Capacity | 9000-36000 bottles per hour |

| (500ml bottle) | ||

| 8 | Glue Consumption | l kg/ 100,000bolttle |

| (label height:50mm) | ||

| 9 | Compressed Air Pressure | MIN5.0bar MAX8.0bar |

| 10 | Consumption of Compressed Air | 0.2M³/minute |

| 11 | Overall dimension | 2500Kg |

| 12 | Total Weight | L=3150,W=1770,H=1800 |

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |