Welcome to XINMAO, your premier provider of comprehensive bottling solutions for cook edible oil.

Whether you are looking to bottle your products in PET, glass, or cans,our advanced technology and expertise ensure the highest quality and efficiency in your production process.

Application Cook edible oil

Type PET Bottle, Glass Bottle

Filling system Metering type, weighing type

Filling speed 1000-36,000BPH (500ml)(Customized)

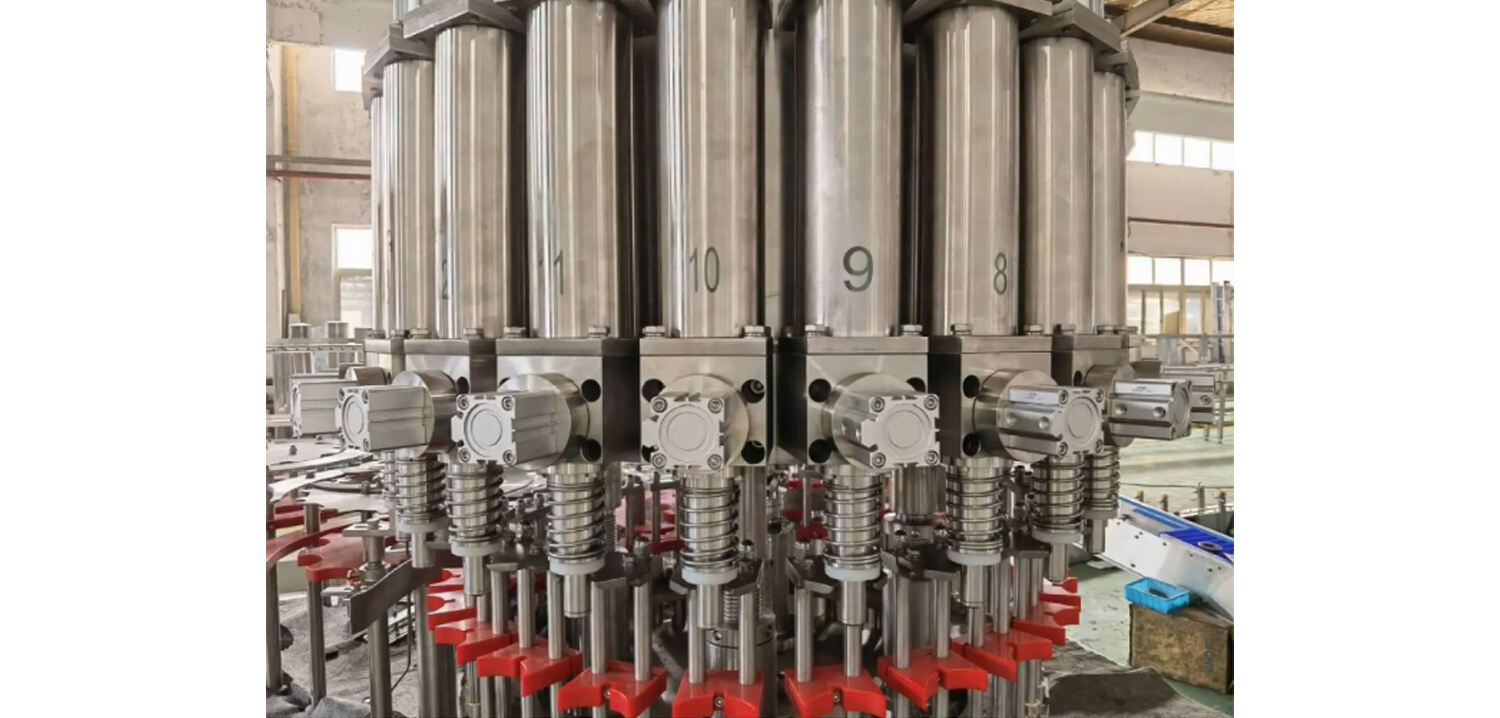

XM series features weighing sensors with high accuracy and is special for filling of edible oil, jam, honey and other viscous products, capping and equipped with rotary transmission, PLC and frequency adjuster in speed, featuring reasonable in structure, safe to operate and easy to maintain, which is an ideal choice for edible oil and viscous product producers.

Compact structured, good-looking, easy to operate and highly automated.

Parts with contact with material are all made of stainless steel of food-grade, no dead angles and easy to clean up.

Filling volume is controlled with film valves to ensure accurate filling.

High-speed and highly accurate filling valves with weighing sensors ensure no loss of liquid at high speed.

Liquid buffer element specially designed inside filling valves can eliminate the cutting affection and wallop between liquid and container, easy to eliminate the air bubble in material.

Capping heads are magnetic constant-torque equipped to ensure capping quality with no damage.

Highly effective cap sorting and feed in system is protective for feed in and cap absence.

Equipped with overload system to safeguard machine and operators.

Equipped with cap absence detector and bottle jam-up detector, which could stop the monoblock in that case.

Equipped with output calculating function for monoblock.

Main electronic components (touch screen, PLC and frequency inverter) are imported products.

1,Automatic PET Bottle Blow Molding Machine

Bottle blowing machine is to make plastic bottles for mineral/pure water, carbonated drink, juice and so on. It is widely used in the food and beverage package industry.

Capacity range: 1,000-20,000PCS/H

Applicable bottle size: Within 2L

Applicable bottle material: PET

Product can be filled: Mineral water, pure water, carbonated drink, soft drink, soda water, etc.

Applicable bottle design: Various kinds of bottle design, customized according to user's request.

Automation degree: Fully automatic

Advantages of this machine that you may concern about:

(1) High production rate

(2) Labor saving

(3) Energy saving

(4) Realize direct connection from blowing to filling

(5) Low failure rate

2,Filling System

Automatic Rotary Type Oil Washing Filling Capping 2in1 Machine (Monoblock Type)

This type filler is used for products without gas contained filling. Automatic achieve bottle inlet ,quantified filling,bottleoutlet ,etc .especially for wine ,foodstuff ,beverage ,mineral water ,condiment and so on. It is a nice choice forfoodstuff,pharmacy ,chemical industries.

1,High precision ,also equipped with devices to adjust the filling volume,accurate adjusting, easy operation.

2.Adjustable middle pillar, no need to change parts when adjust the height. Change some parts can be suitable for different diameter, different shape bottles.

3.The filling volume can be adjusted automatic or single adjusted by manual and adjustable clutch-production device. To make sure the machine can work smoothly during the filling volume regulating.

4.Special device designed such as holding bottle elevating device with this machine can product bottles to avoid bottle broken or damage the filling heads.

5.The parts of this machine which will contact the filling products are made of high quality stainless steel. More safety,environmental ,sanity ,nice look.

| Filling Machine | Model | Capacity(BPH) | Bottle Size | Power |

| Gravity Type | GYF-12-5F | 3000 |

Round&Square PET bottle, 0.3-2.5L bottle,30mm bottleneck |

1.5 |

| GYF-16-5F | 5000 | 2.2 | ||

| GYF-24-8F | 7500 | 3 | ||

| GYF-32-8F | 10000 | 3 | ||

| GYF-12-5F | 1000 |

Round &Square PET botle 3-6L bottle |

1.5 | |

| GYF-20-5F | 1500 | 2.2 | ||

| GYF-32-6F | 2500 | 3 | ||

| Weight Type | GYF-12-5C | 3500 |

Round &Square PET bottle, 0.3-2.5L bottle,30mm bottleneck |

1.5 |

| GYF-16-5C | 5500 | 2.2 | ||

| GYF-24-8C | 8000 | 3 | ||

| GYF-32-8C | 11000 | 3 | ||

| GYF-12-5C | 1200 |

Round &Square PET botle 3-6Lbottle |

1.5 | |

| GYF-20-5C | 1800 | 2.2 | ||

| GYF-32-6C | 2800 | 3 | ||

| Plunger Type | GYF-12-5Z | 4100 |

Round &Square PET bottle 0.3-1L bottle |

1.5 |

| GYF-16-5Z | 5500 | 2.2 | ||

| GYF-24-8Z | 8250 | 3 | ||

| GYF-32-8Z | 11000 | 3 |

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |

3,Labeling Machine

There are mainly three kinds labeling machine, PVC sleeve shrink labeling machine, self adhesive labeling machine and OPP hot glue labeling machine.

4,Laser coding

5,Packaging Machine

There are mainly two kinds of case packing machines, film shrink wrapping machine and carton packing machine. For film shrink wrapping machine, there is also with for unprinted film and for printed film, then there is also shrink film with carton tray. For carton packing machine, there is tape sealing type and hot glue sealing type.