Welcome to XINMAO, your trusted partner for comprehensive beer bottling solutions.

Whether you are bottling beer in glass,cans or PET our advanced technology and expertise ensure the highest quality and efficiency in your production process.

Application Beer, carbonated alcoholic drinks, liquor

Type Glass Bottle, Aluminum Can, PET Bottle

Filling system Isobaric

Filling speed 1000-36,000BPH (500ml)(Customized)

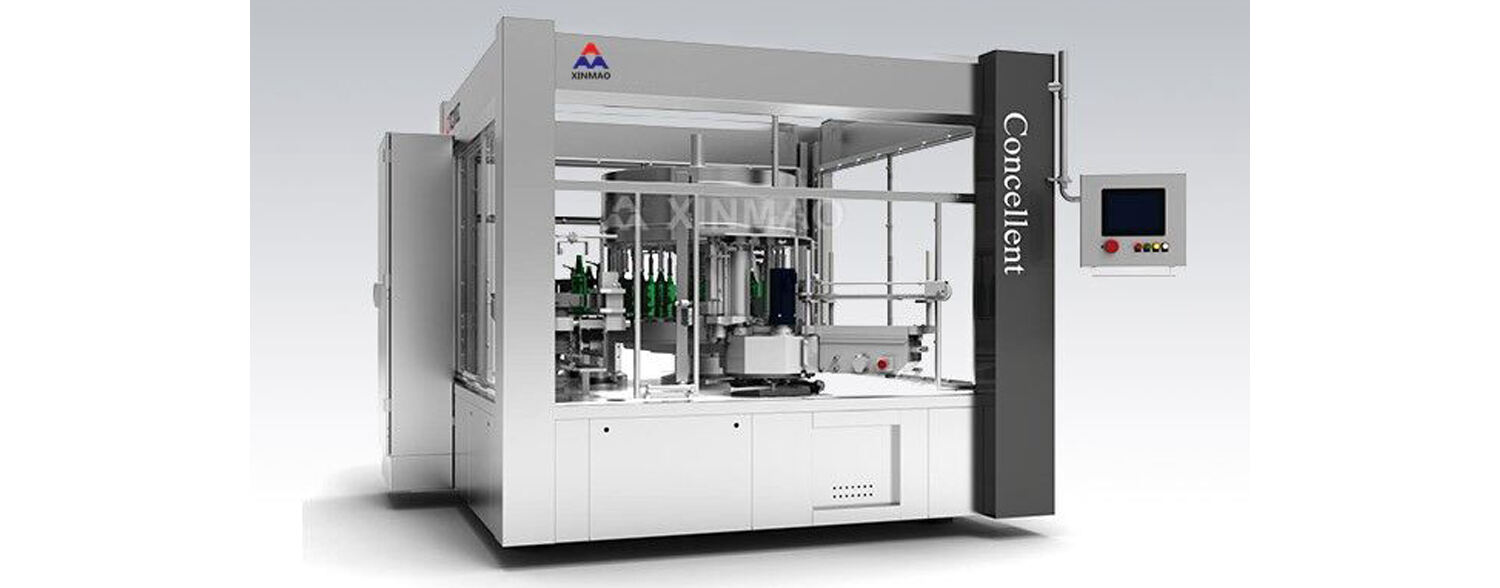

Automatic glass bottle Soft drinks rinser filler capper 3-in-1 filling Triblock, combined with rinsing, filling and capping. It is innovated and designed in the requirement of carbonated soft drinks, beer, energy drink, and soda water, on the basis of introducing, digesting and absorbing advanced technology from Germany.

The machine is a full-automatic multiple-function washing, filling and capping unit. It is used in washing. filling and sealing all kinds of carbonated drinks such as beer, soft drink, energy drink mineral water and pure water. The line has features of unique design,new style, complete functions,multi-purpose, convenient in operation, compact construction, high automaticity. It is the best filling equipment in China.

1.Beer Brewing Machine

Carbonated beverages are mainly composed of water, syrup and carbon dioxide. The syrup is made through sugar melting pots and mixing tanks. After filtering, it is pumped into the syrup tank in the carbonated beverage mixer. At the same time, the sterilized product water is also pumped into the beverage mixer. The water tank is vacuum degassed to facilitate the mixing of carbon dioxide. Through the proportioning system on the beverage mixer, the water and syrup are mixed in proportion to achieve the desired taste. Under the action of controlling the appropriate pressure, the carbon dioxide is dissolved into the material. , it can be made into carbonated beverages with ideal air-locking capacity.

2.Filling System

The high precision mechanical filling valve is adopted,which has the characteristics of no vacuum without bottle.Open gear combined with gearbox transmission, with clutch device, frequency control equipment to expand the speed modulation range.

This machine has a self-lubricating device, and the lubrication point can lubricate the machine regularly High efficiency, low noise, long life.Some parts of the machine can be adjusted to suit different bottle types.The liquid height in the bottle is controlled by an electronic probe to make the level more accurate.

| Model | Output/Capacity |

| DXGF8-8-3 | 1000-2000 BPH |

| DXGF14-12-5 | 2000-3000 BPH |

| DXGF18-18-6 | 3000-4000 BPH |

| DXGF24-24-8 | 5000-6000 BPH |

| DXGF32-32-10 | 8000-10000 BPH |

| DXGF40-40-12 | 10000-12000 BPH |

| DXGF50-50-12 | 12000-15000 BPH |

| DXGF60-60-15 | 15000-18000 BPH |

| DXGF72-72-18 | 18000-24000 BPH |

| DXGF80-80-24 | 21000-30000 BPH |

Conveyor

Bottle in-feed

Rinser

Filler

Capper

Cap elevator

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |

3.Pasteurizer Tunnel

The filling machine adopts the structure of feeding glass bottles by feeding screw, automatically flushes the bottles, and adopts the principle of lifting and lowering of the filling valve, so that the whole line conveys the bottles smoothly.

The constant pressure filling principle is used for fixed liquid level filling, and the secondary valve opening technology is used to meet the full liquid level filling process requirements.

The rotary cap adjuster adopts pneumatic cap management, which has the functions of not damaging the surface of the cap, sending a signal for the lack of cap in the hopper, and controlling the capping machine to automatically replenish the cap.

The whole machine adopts man-machine interface operation, German SIEMENS is automatic control technology such as computer program automatic control, frequency conversion stepless adjustment and other automatic control technologies, with low temperature automatic shutdown, automatic control of feeding and reflux.

4.Labeling Machine

We offer several different types bottle labeling machine based on your requirement. Machines can be used for cold glue label,PVC sleeve label, self-adhesive label, OPP/BOPP label.

Cold glue labeling machine:

1.Fast labeling speed and high precision for containers of different materials and shapes;

2.Make cold glue labels smoother and more beautiful;

3.The scraper angle is specially adjusted to keep the glue at a reasonable thickness, saving adhesive costs;

4.Increase production and bring you greater benefits.

Sticker labeling machine:

After the bottle-separating mechanism separates the products, the sensor detects the passing of the product and sends a signal back to the labeling control system. The control system controls the motor to send out the label and attach it to the position where the product is to be labelled. The product flows through the labeling device and the labeling tape Drive the product to rotate, the label is rolled over, and the sticking action of a label is completed.

PVC labeling machine:

When a bottle on the conveyor belt passes through the bottle detection eye, the servo-controlled drive group will automatically send a label, and the brushing wheel group will brush the next label, and the label will be sleeved on the bottle.

OPP labeling machine:

Is used in continuous roll label sticking on bottles by hot glue. It uses local glue spraying method. It consumes less glue and has low running cost. The maximum speed is 600BPM, which is mainly suitable for high-level drinking water and soft drink.,etc production.OPP labeling machine working more high speed and quiet, low glue consumption, compare with shrink label, its lower cost in material.

5.Packing System

The biggest advantage of Xinmao's film packaging machine is that the cutter is of very good quality and will not break even after many years of use. Foreign famous brands also use this configuration.

The cutter of the film packaging machine with general configuration cannot cut after a few years, and the film sticks and the sealing is not good. In addition, it is very expensive to replace a cutter, which increases the cost of the enterprise. However, our cutter will never have this problem.

This packing machine combines a classic, user-friendly design with advanced features like "bottles vibration" technology to prevent squeezing. Its extended conveyor and host length improve bottle sorting and overall performance.

With over 90% high-quality imported electrical components and a history of stability, it's a top choice for automatic film packing.

6.Bottle De-palletizer

The depalletizer is mainly used in the unloading of glass bottles and cans. The empty cans stacked on the pallet are pushed to the mesh conveyor layer by layer from top to bottom. The unloading of glass bottle is automatically controlled by PLC programmable computer. The depalletizer adopts frequency conversion motor, frequency conversion speed regulation, computer control, and the conveying is stable, smooth and reliable; automatic control technology, mechatronics technology, network technology, computer-controlled automatic operation. The reciprocating cycle automatic stacking meets the set requirements.

Replacing manual tank discharge and traditional empty tank unloader can save a lot of labor and improve production capacity. The programmable computer control system is adopted to improve the accuracy of the mechanical action, and the operation is easy. The pallet lifting table is self-locking and lifting, and the pallet stacking machine adopts cylinder lifting and lowering.