Water Filing Machine is equipment used in drinking water automatic filing operations, offering efficiency, reliability and precision in the packaging of bottle water products .suitable for various sizes and capacities the processing including washing filing capping are composed in one body of the machines .

Application Mineral water,pure water,still water, RO water, drinking water,spring water, flavor water

Suitable for Within 2L Glass Bottle

Filling system Gravity

Filling speed 1500 - 26,000BPH (Customized)

XINMAO This glass bottle filling machine is for filling pure water into glass bottle, capacity can be 10000 bottled water per hour. It is suitable for glass bottle with aluminum caps.

The water filling machine equipped with a flushing nozzle, with the flushing nozzle, you can clean the machine conveniently.

The electric control cabinet is equipped with touch screen and warning light. You can easily operate the machine with the touch screen. Once any problem occurs, the warning light will flash to remind the staff.

The water filling machine integrates washing filling and capping 3 part, with cap elevator.

All the machine are made of high quality sus304, the filling valve is made of sus316.

6.The drinking water filling machine is fully automatic.

1. Water Treatment System

Industrial Reverse Osmosis Water Purification Systems is used to purify water. This system consists of booster pump, sand filter,activated carbon filter, precision filter, and RO filtering system, water pump, ultraviolet sterilizer and etc.

According to customer's raw water analysis report and the final water standard request, we will suggest customer to choose the suitable water treatment system.

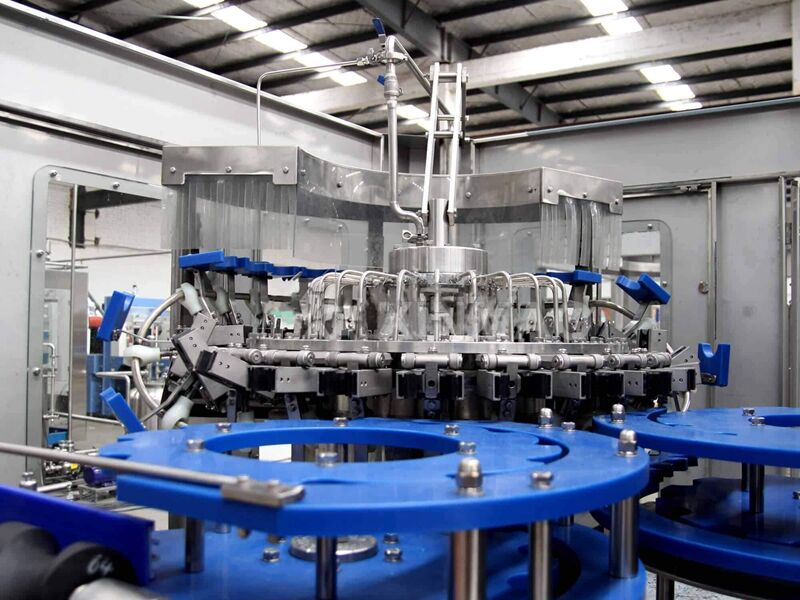

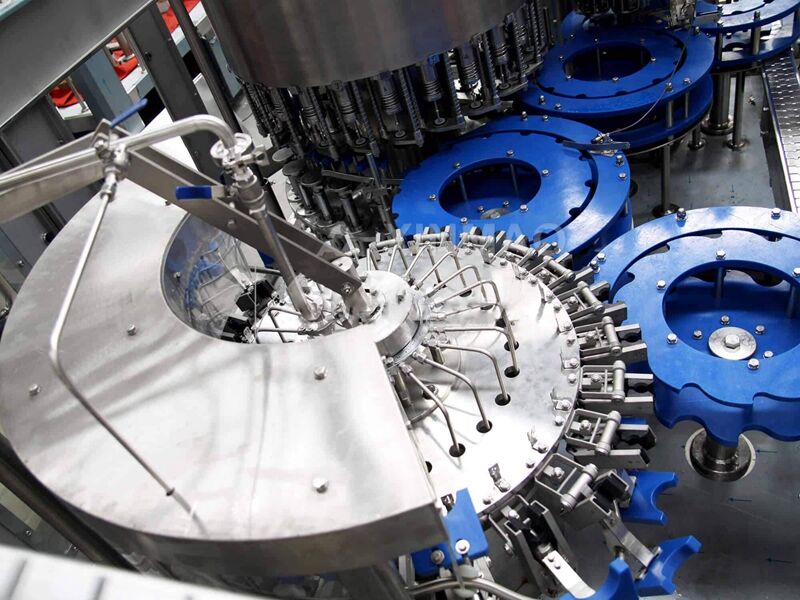

2.CGF Wash-filling-capping 3-in-1 Product introduction:

This CGF Wash-filling-capping 3-in-1 unit: Beverage Machinery is used to produce polyester bottled mineral water, purified water,alcoholic beverage machinery and other non-gas beverage machinery. Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.The Complete Bottled Mineral Water / Pure Water Production Line used in the beverage filling operations.Model: CGF series rotary type

Capacity range: 1,000-36,000 BPH(Customized)

Applicable bottle size: Within 2L

Applicable bottle material: Plastic bottle

Filling method: Normal pressure filling/ Gravity filling

Product can be filled: Water, non-carbonated drink, etc.

Automation degree: Fully automatic

Electricity control system: Germany Siemens PLC

| Model | Output/Capacity (Based on 500ml) |

| CGF8-8-3 | 2000-3000 BPH |

| CGF14-12-5 | 3000-4000 BPH |

| CGF18-18-6 | 5000-6000 BPH |

| CGF24-24-8 | 8000-10000 BPH |

| CGF32-32-10 | 12000-15000 BPH |

| CGF40-40-12 | 15000-18000 BPH |

| CGF50-50-12 | 18000-22000 BPH |

| CGF60-60-15 | 20000-25000 BPH |

| CGF72-72-18 | 25000-36000 BPH |

| CGF80-80-24 | 36000-40000 BPH |

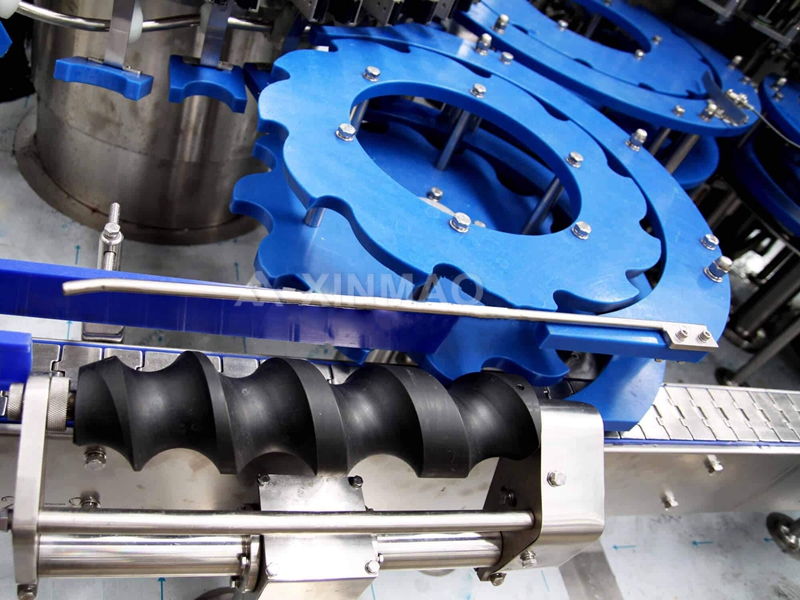

Bottle feeding screw

Rinser

Image above

Filler

Capper

Conveyor

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |

3.Labeling Machine

There are mainly three kinds labeling machine, PVC sleeve shrink labeling machine, self adhesive labeling machine and OPP hot glue labeling machine.

4.Laser coding

5.Packaging Machine

There are mainly two kinds of case packing machines, film shrink wrapping machine and carton packing machine. For film shrink wrapping machine, there is also with for unprinted film and for printed film, then there is also shrink film with carton tray. For carton packing machine, there is tape sealing type and hot glue sealing type.