XINMAO is your premier provider of advanced water bottling solutions.

Our cutting-edge technology and industry expertise ensure that we deliver efficient,high-quality bottling systems tailored to meet your customized needs.

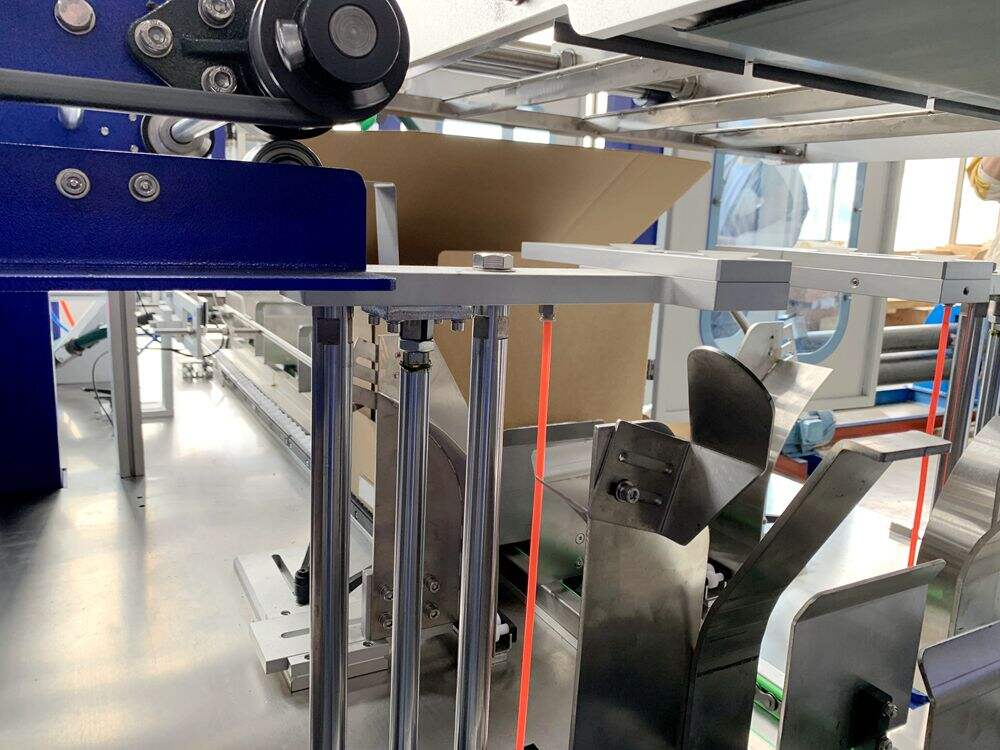

Automatic carton packing machine is used for carton packing in beer, beverage, bottled water, medical treatment, food and other bottled (canned) production line. Packing with cardboard saves about 1/5 of the cost of packaging materials compared with traditional packaging methods. Carton packing machine speed from 10PPM up to 80PPM normally. Carton packing is good for long distance transportation, which is more famous in market compare with other packs.

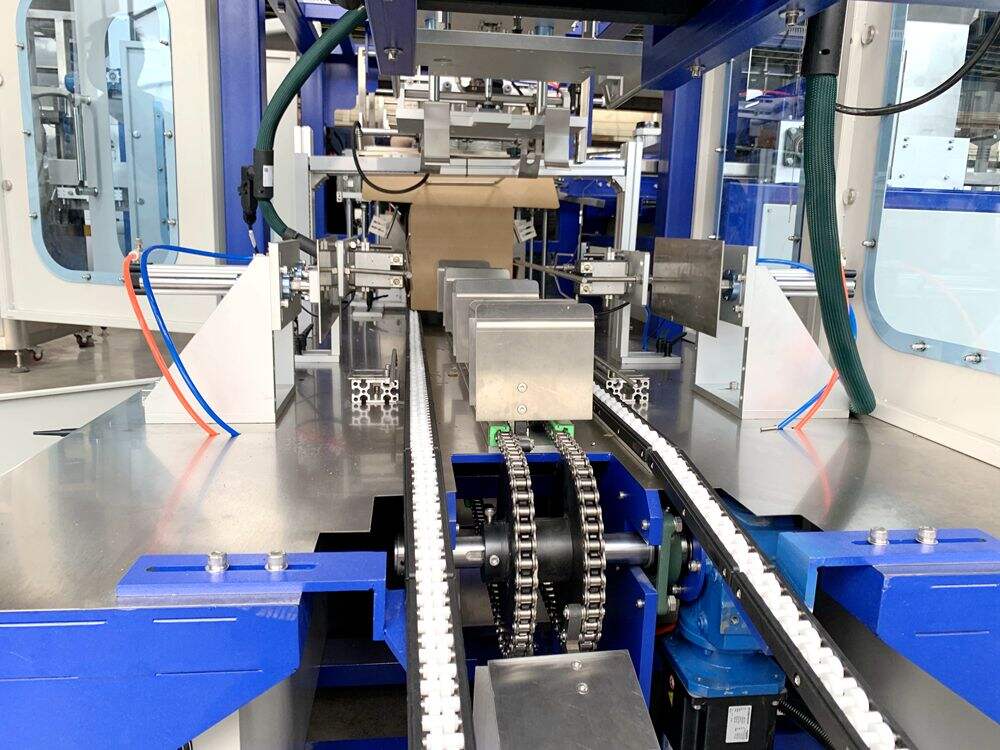

Specially designed for packaging metal cans, paper cans, glass jars, glass bottles, plastic jars, and plastic bottles, the series of caton packing machine from XINMAO is a continuous motion wraparound case packer capable of reaching speeds up to 25 cases/trays per minute.

The XINMAO Wraparound carton packer machine uses up to 20% less corrugated material than conventional regular slotted case packing systems. The system collates the products, loads the corrugated cases or trays, and closes them with hot-melt glue. The XINMAO-4500 provides tight packages minimizing the need for partitions while protecting glass containers from damage. If needed, the system options allow for automatic insertion of partitions, dividers, or pads to increase product protection.

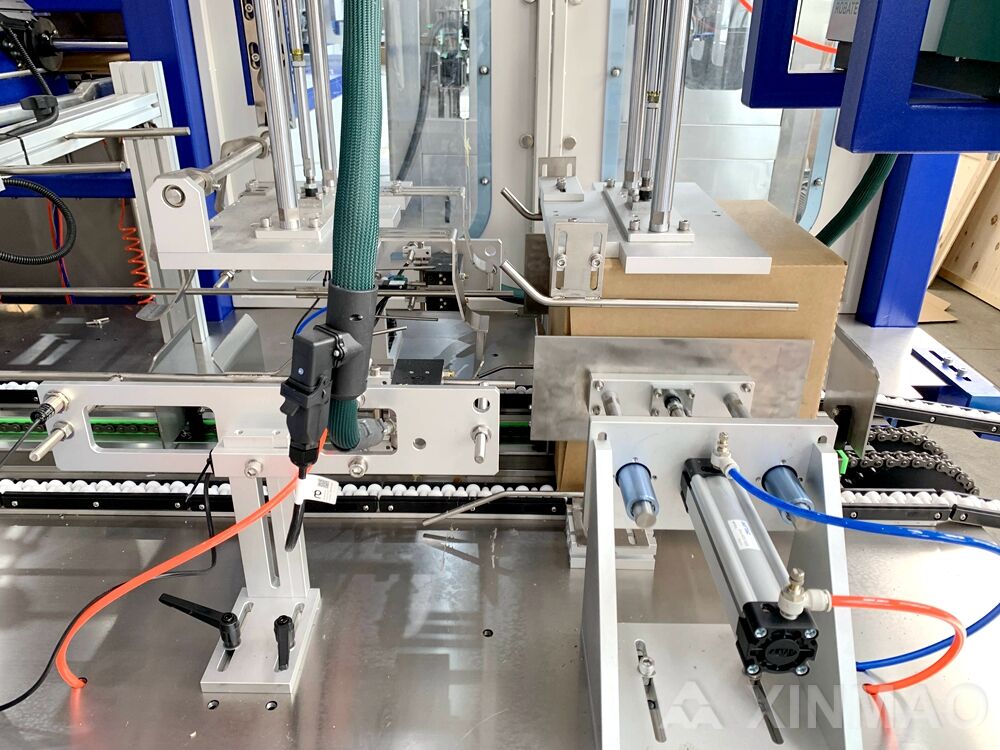

This machine receives the product, groups the product into patterns, automatically feeds corrugated blanks, forms the blanks around the product pattern, applies hot-melt glue, holds the wraparound case in compression, and produces a finished, shippable case. The system is easily adjustable for varying product sizes, speeds, and product patterns. The machine runs trays as well as wraparound cases.

A rugged machine that minimizes labor requirements, increases productivity and reduces packaging materials. The machine integrates easily into new or existing lines of packaging equipment.

Main Features of Carton Packing Machine

1.Nice profile, friendly operation and low maintenance;

2.Siemens PLC, provide remote servicing and diagnosis assistance if required;

3.Full automatic 9 sets of Siemens Servo-control, realize perfect synchronization;

4.Large colorful touch screen, operation interface in English version;

5.Stable hot melt elements, reliable carton box forming and sealing.

| PROJECT | Wrap around carton packing machine |

| Model | XM-PT-P |

| Applicable Container | Plastic bottle, Glass bottle, Tins and Cans |

| Product Size | 250ML-2000ML |

| Container Diameter | 57-100(or larger)mm |

| Capacity | 25 Cartons/per min |

| Machine Dimension(L*W*H) | L6285*W2582*H2115mm |

| Carton Size | 500 < L+W+H< 1000 |

| Hot Melt Glue Solidify | 1.5-2s |

| Working Pressure | 0.4-0.7Mpa |

| Power | 15KW |

| Weight | 4000 KG |

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |